Scheme 7.1 The spectrum of uses for polymers in pharmaceutics

7.1.1 Definitions

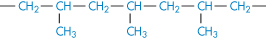

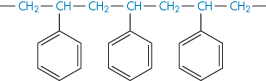

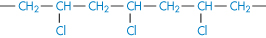

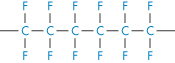

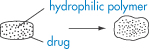

Polymers are substances of high molecular weight made up of repeating monomer units. Substances with short chains containing relatively few monomers are called oligomers. Polymers owe their unique properties to their size, their three-dimensional shape and sometimes to their flexibility and asymmetry. The chemical reactivity of polymers depends on the chemistry of their monomer units, but their properties depend to a large extent on the way the monomers are assembled; it is this fact that leads to the versatility of synthetic polymers. Polymer molecules may be linear or branched, and separate linear or branched chains may be joined by crosslinks. Extensive crosslinking leads to a three-dimensional and often insoluble polymer network. Polymers in which all the monomeric units are identical are referred to as homopolymers; those formed from more than one monomer type are called copolymers. Various arrangements of the monomers A and B in the copolymer molecules (Fig. 7.1) can be produced with consequent effects on the physical properties of the resulting polymer. Synthetic polymers may have their main chains substituted in different ways, depending on the conditions of the reaction, such that atactic (random), isotactic or syndiotactic forms are produced, as diagrammatically represented in Fig. 7.1.

Figure 7.1 (a) Varieties of copolymer molecular structures attainable though the polymerisation of two different monomers represented by A and B. (b) Representations of random atactic, isotactic and symmetrical copolymers.

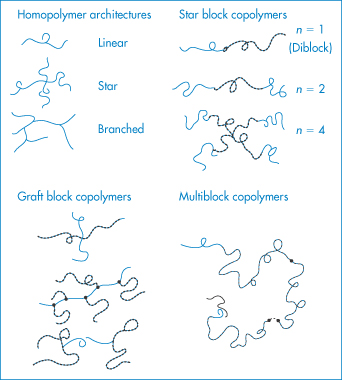

Copolymers may be described as alternating copolymers, block copolymers or graft copolymers. The molecular architecture of copolymers may, however, be more complicated than represented in Fig. 7.1. Block copolymers such as the polyoxyethylene–polyoxypropylene–polyoxyethylene (ABA) systems have both hydrophobic (A) and hydrophilic regions (B); they form an interesting group of surfactants and are discussed in Chapter 5. Homopolymers can be linear, star or branched (Fig. 7.2), giving rise to so-called star block copolymers defined by the number of arms (n).

Figure 7.2 The range of structures of homopolymers and star block, graft block and multiblock copolymers.

Polymers that have fairly symmetrical chains and strong interchain forces can be drawn into fibres. Plastics are polymers with lower degrees of crystallinity that can be moulded. Further down the rigidity scale are rubbers and elastomers, whose properties are well known.

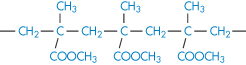

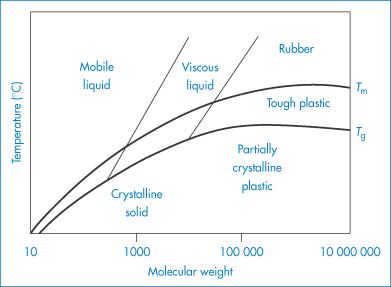

It is apparent that polymer molecules will have a much wider range of physical properties than small chemical entities. Even when considering one chemical type (for example, polyethylene), its properties may be altered by increasing or decreasing the molecular weight (Fig. 7.3). There is a degree of control over properties that is not present with small organic materials. It is because of this that synthetic polymers also have an advantage over many variable natural polymers, although many natural derivatives such as cellulosic derivatives are used extensively. Natural materials can be modified chemically, and this approach can lead to useful new products, as with those derived from cellulose or dextran. The structural formulae of some common macromolecules are given in Table 7.1.

Figure 7.3 Approximate relation between molecular weight, glass transition temperature (Tg), melting point (Tm) and polymer properties.

Reproduced from Billmeyer FW. Textbook of Polymer Science, 2nd edn. New York: Wiley; 1971.

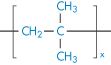

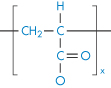

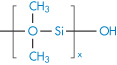

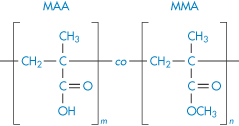

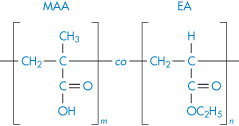

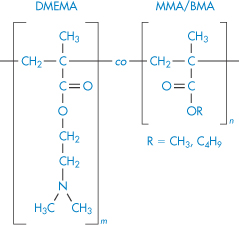

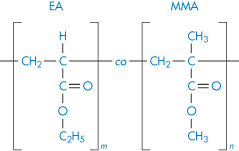

Table 7.1 Structural formulae of some macromolecular compounds

Name | Chain structure | Monomer |

Polymers with a carbon chain backbone | ||

Polyethylene |

|

|

Polypropylene |

|

|

Polystyrene |

|

|

Poly(vinyl chloride) |

|

|

Polytetrafluoroethylene |

|

|

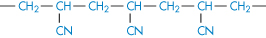

Polyacrylonitrile |

|

|

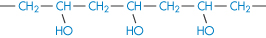

Poly(vinyl alcohol) |

|

|

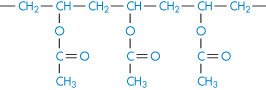

Poly(vinyl acetate) |

|

|

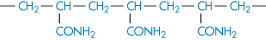

Polyacrylamide |

|

|

Poly(methyl methacrylate) |

|

|

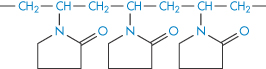

Polyvinylpyrrolidone |

|

|

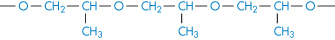

Polymers with a heterochain backbone | ||

Poly(ethylene oxide) |

|

|

Poly(propylene oxide) |

|

|

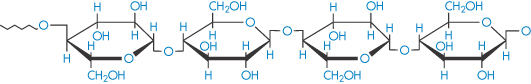

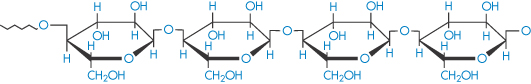

Cellulose (polyglucoside, β → 1,4) |

|

|

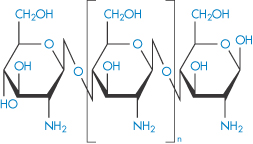

Chitosan |

|

|

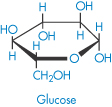

Amylose (polyglucoside, α → 1,4) (component of starch) |

| Glucose |

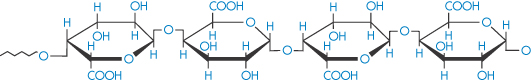

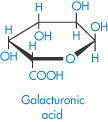

Pectinic acid (polygalacturonoside, α → 1,4) (jelly-forming component of fruits) |

|

|

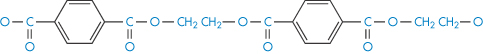

Polyethylene glycol terephthalate |

|

|

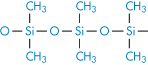

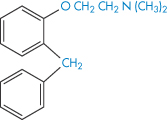

Polydimethylsiloxane |

|

|

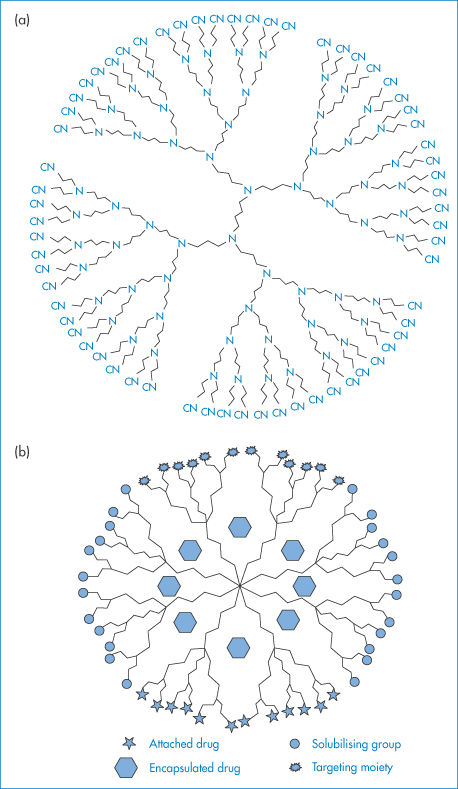

Dendrimers are highly branched polymer constructs formed from a central core that defines their initial geometry.1 Their branch-like structure (Fig. 7.4) leads to spheres, which in higher generations appear to be the size of micelles, and ultimately nanospheres of small dimensions. They can be functionalised and in this way ‘layered’ systems can be formed by using different monomers for succeeding reactions (generations); such chemical architecture has virtually no bounds.2 Dendrons are partial dendrimers, usually having a branched structure coupled to a linear chain.

Figure 7.4 (a) A two-dimensional view of a dendrimer with 64 cyano functional groups. It is possible to trap small to medium-size molecules in dendrimers that have pores of appropriate dimensions between the branches of the structure. (b) A diagrammatic representation of possible sites for covalent attachment of drugs, solubilising groups and targeting moieties, and encapsulation of drugs.

(a) Reprinted by permission from Macmillan Publishers Ltd: Nature. Gibson HW. Architectural delights. Nature 1994;371:106, copyright 1994.

7.1.2 Polydispersity

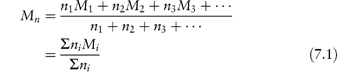

Nearly all synthetic polymers, possibly with the exception of dendrimers and some low-molecular-weight systems, and naturally occurring macromolecular substances exist with a range of molecular weights; exceptions to this are proteins and natural polypeptides, each of which occurs with a single well-defined molecular weight. The molecular weight of a polymer or macromolecule is thus an average molecular weight, which may be determined by chemical analysis or by osmotic pressure or light-scattering measurements. When determined by chemical analysis or osmotic pressure measurement a number-average molecular weight, Mn, is found, which in a mixture containing n1, n2, n3, … moles of polymer with molecular weights M1, M2, M3, …, respectively, is defined by

The individual molecular weights M1, M2, … cannot be determined separately – the equation merely explains the meaning of the value Mn.

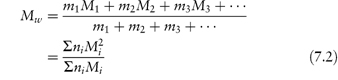

In light-scattering techniques, larger molecules produce greater scattering; thus the weight (or, more strictly, the mass) rather than the number of the molecules is important, giving a weight-average molecular weight, Mw:

In equation (7.2) m1, m2, m3, … are the masses of each species, and mi is obtained by multiplying the molecular weight of each species by the number of molecules of that weight; that is, mi = niMi. Thus the molecular weight appears as the square in the numerator of equation (7.2); the weight-average molecular weight is therefore biased towards larger molecules. Another consequence is that Mw > Mn; that is, the average molecular weight of a polymer measured by light scattering must be greater than that obtained by osmotic pressure measurements if the polymer is polydisperse (that is, contains a range of molecular weights). The ratio Mw/Mn expresses the degree of polydispersity. Table 7.2 shows actual values for the number-average and weight-average molecular weights for dextrans, microbial polysaccharides used therapeutically as plasma expanders.

Table 7.2 Number- and weight-average molecular weights for dextran fractions

Fraction | Mn | Mw | Mw/Mn |

A | 41 000 | 47 000 | 1.14 |

B | 38 000 | 50 000 | 1.31 |

C | 64 000 | 76 000 | 1.18 |

D | 95 000 | 170 000 | 1.79 |

E | 240 000 | 540 000 | 2.25 |

Reproduced from Wales M et al. Intrinsic viscosity-molecular weight relationships for dextran. J Polymer Sci 1953;10:229. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission.

7.1.3 Polymer mixtures or blends

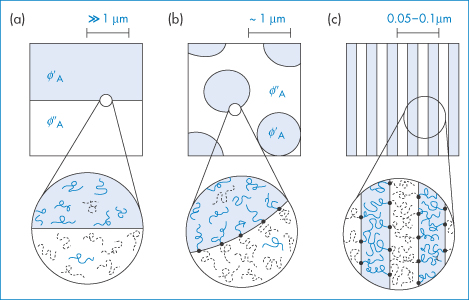

Of course not all polymers are soluble or miscible with each other; some indeed de-mix when added together. The different phase behaviours that are realised with representative molecular architectures are shown in Fig. 7.5. Such mixtures produce solid polymeric structures such as films and membranes with distinctive morphologies and properties. When polymer blends are used as drug delivery matrices or as the basis of micro- and nanoparticles, it is important that polymer–polymer interactions are studied.

Figure 7.5 Representative polymer–polymer phase behaviour with different molecular architectures. Microphase separation (a) results when thermodynamically incompatible linear homopolymers are mixed. The covalent bond between blocks in a diblock copolymer leads to microphase segregation (c). A mixed architecture of linear homopolymers and the corresponding diblock copolymer produces a surfactant-like stabilised intermediate-scale phase separation (b).

7.1.4 Polymer solubility

The solubility of polymeric substances in water is determined by the same considerations that apply to smaller molecules. Those polymers that are sufficiently polar will be able to interact with the water to provide energy to remove individual polymer chains from the solid state.

Water-soluble polymers have an ability to increase the viscosity of solvents at low concentrations, to swell or change shape in solution, and to adsorb at surfaces. These are significant features of their behaviour, which we will deal with briefly.

Insoluble polymers or polymers with a low rate of solution are used more to form thin films, as film-coating materials, surgical dressings or membranes for dialysis or filtration, or to form matrices for enveloping drugs to control their release properties, or simply as packaging materials.

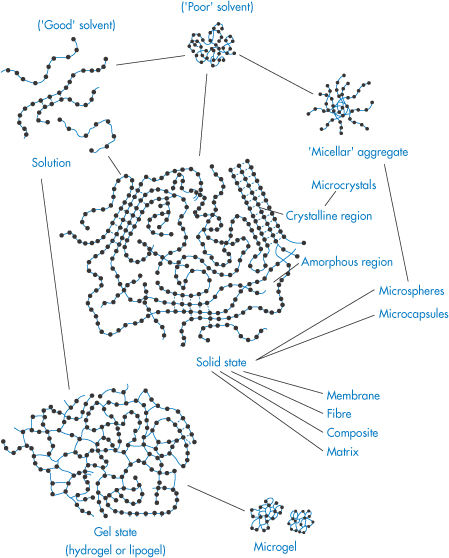

Figure 7.6 illustrates the variety of morphologies that polymeric systems can adopt depending on the nature of the solvent, the polymer concentration and the nature of the polymer itself. Such diversity explains the wide range of uses in pharmacy and medicine.

Figure 7.6. Representation of the variety of polymer morphologies in solution and in the gel (or microgel) or solid states. In solution the conformation of the polymer depends on the nature of polymer–solvent interactions and whether or not the polymer chains associate to form micellar aggregates. Crystals of polymer and microcrystals can be prepared, and gels can be formed from covalently crosslinked chains or polymer chains associated by hydrogen bonding or hydrophobic interactions. Listed are the forms in which most polymers can be fabricated: membranes, fibres, composites, matrices; microspheres and microcapsules can also feature, as discussed later in this chapter.

|

|

7.2 Water-soluble polymers

The rate of solution of a water-soluble polymer depends on its molecular weight: the larger the molecule, the stronger are the forces holding the chains together. More energy has to be expended to force the chains apart in the solvent. The greater the degree of crystallinity of the polymer, the lower the rate of solution.

The velocity of penetration (S) of a solvent into the bulk polymer obeys the relationship

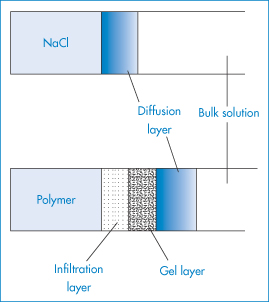

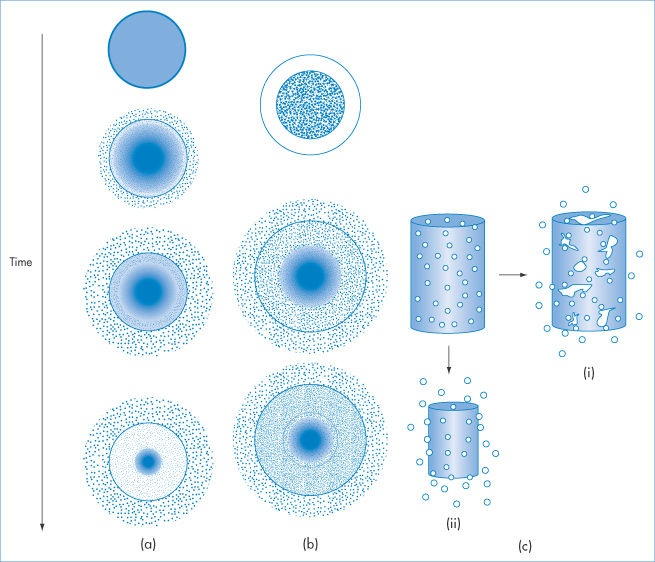

where M is the polymer molecular weight, k and A being constants. The dissolution process, however, is more complicated than with ordinary crystalline materials. It is frequently observed that swollen layers and gel layers form next to the polymer (Fig. 7.7). If a drug is embedded in the polymer, the drug has to diffuse through these gel layers and finally through the diffusion layer.

Figure 7.7 Penetration of solvent into (top) soluble crystalline material and (bottom) polymer compared.

It is the combination of slow solution rate and the formation of viscous surface layers that makes hydrophilic polymers useful in controlling the release rate of soluble drugs (see section 7.5). Choice of appropriate polymer molecular weight controls both the rate of dissolution and the viscosity of its resulting solution. A balance between rate of polymer solution and viscosity of the solution layer must be achieved in controlled-release systems. If the polymer solution rate is too slow, then soluble drug is leached out with little retardation.

The bulk viscosity of polymer solution is an important parameter also when polymers are being used as suspending agents to maintain solid particles in suspension by prevention of settling (see Chapter 6) and when they are used to modify the properties of liquid medicines for oral and topical use.

7.3 General properties of polymer solutions

7.3.1 Viscosity of polymer solutions

The rheology of colloidal solutions and suspensions has been discussed in Chapter 6. Here we consider the particular use of viscosity measurements to determine the average molecular weights and asymmetry of polymeric molecules.

The presence in solution of large macromolecular solutes has an appreciable effect on the viscosity of the solution. From a study of the viscosity as a function of polymer concentration it is possible to gain information on the shape or hydration of these polymers in solution and also their average molecular weight. The assumption is made in this section that the solution exhibits Newtonian flow characteristics.

As discussed in Chapter 6 (section 6.3), the viscosity of solutions of macromolecules is conveniently expressed by the relative viscosity,  rel, defined as the ratio of the viscosity of the solution,

rel, defined as the ratio of the viscosity of the solution,  , to the viscosity of the pure solvent

, to the viscosity of the pure solvent  0; the specific viscosity,

0; the specific viscosity,  sp, defined as

sp, defined as  rel – 1; and the reduced viscosity

rel – 1; and the reduced viscosity  sp/

sp/ (where

(where  is the volume fraction, defined as the volume of the particles divided by the total volume of the solution). The ratio

is the volume fraction, defined as the volume of the particles divided by the total volume of the solution). The ratio  sp/

sp/ for ideal solutions is independent of solution concentration. In real solutions the reduced viscosity varies with concentration owing to molecular interactions so it is usual to extrapolate plots of

for ideal solutions is independent of solution concentration. In real solutions the reduced viscosity varies with concentration owing to molecular interactions so it is usual to extrapolate plots of  sp/

sp/ versus

versus  to zero volume fraction. The extrapolated value is called the intrinsic viscosity [

to zero volume fraction. The extrapolated value is called the intrinsic viscosity [ ].

].

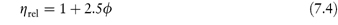

Einstein showed from hydrodynamic theory that for a dilute system of rigid, spherical particles

i.e.

where  is the volume fraction of the particles, defined as the volume of the particles divided by the total volume of the solution. In other words, the intrinsic viscosity [

is the volume fraction of the particles, defined as the volume of the particles divided by the total volume of the solution. In other words, the intrinsic viscosity [ ] of this ideal system is 2.5.

] of this ideal system is 2.5.

For polymers of high molecular weight, the value of  sp/

sp/ varies with solution concentration (which is directly related to

varies with solution concentration (which is directly related to  ). The concentration dependence is often expressed as

). The concentration dependence is often expressed as

where k is a constant referred to as the Huggins’ constant. At moderate concentrations a plot of  sp/c against c is linear with a gradient equal to k. The value of this constant provides a useful indication of the extent of interaction between the polymer and the solvent; for flexible polymer molecules in a ‘good’ solvent (see below) k often has a value of approximately 0.35.

sp/c against c is linear with a gradient equal to k. The value of this constant provides a useful indication of the extent of interaction between the polymer and the solvent; for flexible polymer molecules in a ‘good’ solvent (see below) k often has a value of approximately 0.35.

Departure of the limiting value of  sp/

sp/ from the theoretical value of 2.5 may result from either hydration of the particles, or from particle asymmetry, or from both.

from the theoretical value of 2.5 may result from either hydration of the particles, or from particle asymmetry, or from both.

A more general form of equation (7.4) allowing for particle asymmetry is

where the intrinsic viscosity [ ] is replaced by a shape factor ν related to the axial ratio of an ellipsoid. In the case of non-hydrated spheres ν reduces to 2.5.

] is replaced by a shape factor ν related to the axial ratio of an ellipsoid. In the case of non-hydrated spheres ν reduces to 2.5.

The volume fraction is usually replaced by the weight concentration, c. For a macromolecule of hydrodynamic volume vh and molecular weight M,  =c NAvh/M where NA is the Avogadro constant.

=c NAvh/M where NA is the Avogadro constant.

Macromolecules are frequently hydrated, not only with chemically bound water but also with physically entrapped solvent. These two types of water have differing properties; the specific volume v0 (volume per gram) of the entrapped water may be considerably different from that of pure solvent,  . The intrinsic viscosity of the hydrated macromolecule may be written as

. The intrinsic viscosity of the hydrated macromolecule may be written as

where  1 is the number of grams of solvent per gram of dry macromolecular material and

1 is the number of grams of solvent per gram of dry macromolecular material and  is its partial specific volume.

is its partial specific volume.

If the particle can be assumed to be unhydrated, or if the degree of hydration can be estimated with certainty from other experimental techniques, equation (7.8) may be used to determine the asymmetry of the particle. Alternatively, if the macromolecule may be assumed to be symmetrical or its asymmetry is known from other techniques, then this equation may be used to estimate the extent of hydration of the macromolecule.

Shape and solvent effects

As the shape of molecules is to a large extent the determinant of flow properties, change in shape due to changes in polymer–solvent interactions and the binding of small molecules with the polymer may lead to significant changes in solution viscosity. The nature of the solvent is thus of prime importance in this regard. In so-called ‘good’ solvents, linear macromolecules will be expanded as the polar groups will be solvated. In a ‘poor’ solvent, the intramolecular attraction between the segments is greater than the segment–solvent affinity and the molecule will tend to coil up (Fig. 7.6). The viscosity of ionised macromolecules is complicated by charge interactions that vary with polymer concentration and additive concentration. Flexible charged macromolecules will vary in shape with the degree of ionisation. At maximum ionisation they are stretched out owing to mutual charge repulsion and the viscosity increases. On addition of small counterions, the effective charge is reduced and the molecules contract; the viscosity falls as a result. Some of the effects are illustrated later in this chapter in discussion of individual macromolecules.

The viscosity of solutions of globular proteins (which are more or less rigid) is only slightly affected by change in ionic strength. The intrinsic viscosity of serum albumin varies only between 3.6 and 4.1 cm3 g−1 when the pH is varied between 4.3 and 10.5 and the ionic strength between zero and 0.50.

Viscosity in pharmacopoeial specifications

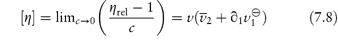

In cases where control of molecular weight is important, for example in the use of dextran fractions as plasma expanders,3 a viscosity method is specified, for example, in the BP monograph. Staudinger proposed that the reduced viscosity of solutions of linear high polymers is proportional to the molecular weight of the polymer or its degree of polymerisation, p:

This empirical law has been modified to

where a is a constant in the range 0–2, which for most high polymers has a value between 0.6 and 0.8, [ ] is the intrinsic viscosity as defined previously, and M is the molecular weight of the polymer. Equation (7.10) is often referred to as the Mark–Houwink equation. For a given polymer–solvent system, K and a are constant. Values of these constants may be determined from measurements on a series of fractions of known molecular weight and hence the molecular weight of an unknown fraction can be determined by measurement of the intrinsic viscosity. The viscosity-average molecular weight is essentially a weight-average since the larger macromolecules influence viscosity more than the smaller ones. The intrinsic viscosity of Dextran 40 BP is stated to be not less than 16 cm3 g−1 and not more than 20 cm3 g−1 at 37°C, while that of Dextran 110 is not less than 27 cm3 g−1 and not more than 32 cm3 g−1.

] is the intrinsic viscosity as defined previously, and M is the molecular weight of the polymer. Equation (7.10) is often referred to as the Mark–Houwink equation. For a given polymer–solvent system, K and a are constant. Values of these constants may be determined from measurements on a series of fractions of known molecular weight and hence the molecular weight of an unknown fraction can be determined by measurement of the intrinsic viscosity. The viscosity-average molecular weight is essentially a weight-average since the larger macromolecules influence viscosity more than the smaller ones. The intrinsic viscosity of Dextran 40 BP is stated to be not less than 16 cm3 g−1 and not more than 20 cm3 g−1 at 37°C, while that of Dextran 110 is not less than 27 cm3 g−1 and not more than 32 cm3 g−1.

|

the relative viscosity, the specific viscosity, the intrinsic viscosity [

|

7.3.2 Gel formation

Concentrated polymer solutions frequently exhibit a very high viscosity because of the interaction of polymer chains in a three-dimensional fashion in the bulk solvent. These viscous crosslinked systems are termed gels. A gel is a polymer-solvent system containing a three-dimensional network of quite stable bonds that are almost unaffected by thermal motion. If such a polymer network is surrounded by the solvent (the system can be arrived at by swelling of solid polymer or by reduction in the solubility of the polymer in the solution) the system is a gel regardless of whether the network is formed by chemical or physical bonds. When gels are formed from solutions, each system is characterised by a critical concentration of gelation below which a gel is not formed. This concentration is determined by the hydrophile–lipophile balance of the polymer and the degree of regularity of the structure, by polymer–solvent interaction, by molecular weight and by the flexibility of the chain: the more flexible the molecule, the higher is the critical gelling concentration. The characteristic features of a gel include the considerable increase in viscosity above the gel point, the appearance of a rubber-like elasticity and, at higher polymer concentrations, a yield point stress. Under small stress the gel should retain its shape, but considerable deformation can occur at higher stress.

Type I and type II gels

Gels can be categorised into two groups, depending on the nature of the bonds between the chains of the network. Gels of type I are irreversible systems with a three-dimensional network formed by covalent bonds between the macromolecules. They include swollen networks, which have been formed by polymerisation of a monomer in the presence of a crosslinking agent.

Type II gels are heat-reversible, being held together by intermolecular bonds such as hydrogen bonds. Sometimes bridging by additive molecules can take place in these type II systems. Poly(vinyl alcohol) solutions gel on cooling below a temperature known as the gel point. The gel point can therefore be influenced by the presence of additives that can induce gel formation by acting as bridge molecules, as, for example, with borax and poly(vinyl alcohol). The gel point of polymers can also be increased or decreased by the addition of solvents that alter the polymer’s affinity for the solvent (Table 7.3).

Table 7.3 Gel points of 10% poly(vinyl alcohol)

Solvent | Gel point (°C) |

Water | 14 |

Glycerol | 64 |

Ethylene glycol | 102 |

Reproduced from Pritchard JG. Poly(vinyl alcohol): Basic Properties and Uses. London: Macdonald; 1970.

Solutions of vinyl alcohol polymers in water are viscous mucilages that resemble those formed by methylcellulose; the viscosity of the mucilage is greatly increased by incorporating sodium perborate or silicate. Because of their gelling properties poly(vinyl alcohol) solutions are used as jellies for application of drugs to the skin. On application, the gel dries rapidly, leaving a plastic film with the drug in intimate contact with the skin. Plastic Film (Canadian Pharmacopoeia) is prepared from poly(vinyl alcohol) and other additives and is intended as a vehicle for acriflavine, benzocaine, ichthammol and other topical drugs.

Depending on the polymer, gelation can occur either with a fall or a rise in the temperature.

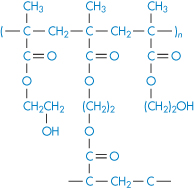

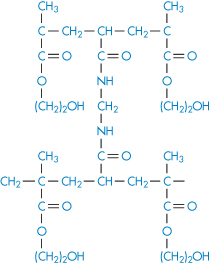

Crosslinked polymeric systems

If water-soluble polymer chains are covalently crosslinked, gels will be formed when the dry material interacts with water. The polymer swells in water but cannot dissolve as the crosslinks are stable. This expansion on contact with water has been put to many uses, such as in the fabrication of expanding implants from crosslinked hydrophilic polymers that imbibe body fluids and swell to a predetermined volume. These materials, such as the poly(hydroxyethyl methacrylate)s (poly(HEMA)s), are insoluble and chemically stable because of their three-dimensional structure (I and II) and do not dissolve. Implanted in the dehydrated state, these polymers swell to fill a body cavity or to give form to surrounding tissues. The gels may be used as vehicles for antibiotics, permitting protracted release of drug in the immediate environment of the implant. Antibiotic-loaded gels like this have been used in infections of the middle ear and other sites not readily reached by other methods of administration. Surgical suture material coated with antibiotic-containing hydrophilic gels acquires a chemotherapeutic role as the development of spread of infection along the suture fibre is prevented.

Structure I Poly(HEMA) crosslinked with ethylene glycol dimethacrylate (EGDMA)

Structure II Poly(HEMA) crosslinked with N, N′-methylene-bisacrylamide (BIS)

Hydrophilic contact lenses (such as Soflens) are made from crosslinked poly(2-hydroxyethyl methacrylates). The emphasis in their development has been on their permeability to oxygen. They have also been used as reservoirs for drug delivery to the corneal surface. Conventional eye drop medication (see Chapter 9) has been modified over the years through the addition to formulations of a variety of viscosity-enhancing agents, polymers such as hydroxypropylmethylcellulose (HPMC), poly(vinyl alcohol) and silicones. These all prolong contact of drug with the cornea by increasing the viscosity of the medium and retarding the drainage of the tear fluid from the eye via the punctae.

Heterogels

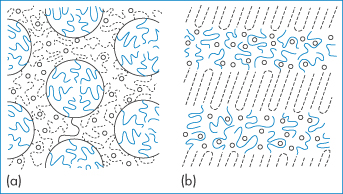

As it is possible to produce macromolecular chains with segments that have different solubilities in a given solvent (copolymers), one would expect that concentrated solutions of such copolymers would behave in a manner different from that of a simple polymer. In block copolymers of the type AAABBBAAA, in which A is water-soluble and B is water-insoluble, the insoluble parts will tend to aggregate. If, for instance, a polystyrene–poly(oxyethylene) copolymer, comprising 41% polystyrene and 59% poly(oxyethylene), is dissolved at 80°C in butyl phthalate (a good solvent for polystyrene), a gel with a microscopic layer structure is formed at room temperature; in nitromethane the form is somewhat different (Fig. 7.8a) as the nitromethane preferentially dissolves the poly(oxyethylene) chains.

Figure 7.8 Structure of a copolymer of type A–B made from polystyrene and polyoxyethylene (a) in nitromethane (cylindrical structure) and (b) in butyl phthalate (layer structure). Nitromethane dissolves the poly(oxyethylene) part preferentially, but butyl phthalate dissolves the polystyrene part. (–––) Polystyrene; (– – –), poly(oxyethylene); (○) solvent.

Reproduced with permission from Sadron F. Angew Chem 1963;2:248.

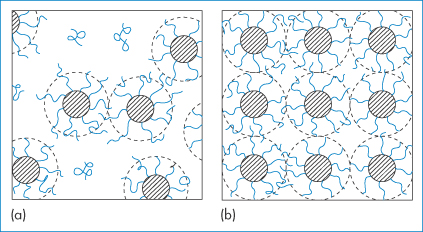

Poly(oxyethylene)–poly(oxypropylene)–poly(oxyethylene) block copolymers, known commercially as Pluronic or poloxamer surfactants, are used as emulsifiers. Some form micellar aggregates in aqueous solutions above a critical micelle concentration, in which the hydrophobic central block associates with other like blocks, leaving the hydrophilic poly(oxyethylene) chains to the outside and protecting the inner core. Packing of these micelles in solution of high concentration leads to the reversible formation of gels, as shown in Fig. 7.9.

Figure 7.9 ABA-type copolymers: (a) micelles in dilute solution; (b) formation of a cubic-phase gel, by packing of micelles.

Syneresis

Syneresis is the term used for the separation of liquid from a swollen gel. Syneresis is thus a form of instability in aqueous and non-aqueous gels. Separation of a solvent phase is thought to occur because of the elastic contraction of the polymeric molecules; in the swelling process during gel formation, the macromolecules involved become stretched and the elastic forces increase as swelling proceeds. At equilibrium, the restoring force of the macromolecules is balanced by the swelling forces, determined by the osmotic pressure. If the osmotic pressure decreases, as on cooling, water may be squeezed out of the gel.

|

|

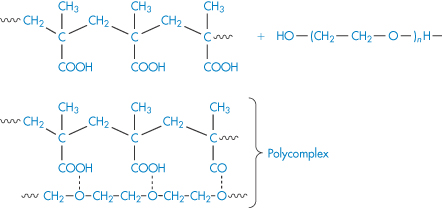

7.3.3 Polymer complexes

The varied structure and chemistry of polymers provide ample opportunity for complexes to form in solution. One example occurs when an aqueous solution of high-molecular-weight polyacids is mixed with polyglycols. The viscosity and pH of the solution of the equimolar mixture of polyacid and glycol remain the same with the increase in oligomer chain length up to a critical point. The nature of the interaction is shown in (III); this occurs only when the polyethylene glycol molecules have reached a certain size.

Structure III Polycomplex formed by interaction of polyacid and polyoxyethylene glycol

Such macromolecular reactions are highly selective and strongly dependent on molecular size and conformation. On mixing, some of the macromolecules might be involved in the complex while the rest will be free. The reason for compositional heterogeneity of the products could be the conformational transitions of macromolecules in the course of complex formation.

Interactions between macromolecules can occur in formulations, for example, when preparations are mixed. They can be put to good advantage in the synthesis of novel compounds. Polyethyleneimine and poly(acrylic acid) form a polyelectrolyte complex with salt-like bonds, as shown in (IV). If the complex is heated as a film, interchain amide bonds are formed between the groups that formed electrostatic links. The non-ionised ‒COOH and ‒NH groups in the chain are the points of structural defects in the film.

Structure IV Complex formation between polyethyleneimine and poly(acrylic acid)

7.3.4 Binding of ions to macromolecules

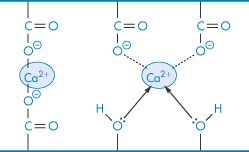

Calcium is coordinated between certain uronic acid-containing polysaccharides (V), which can explain the tight binding of calcium and other multivalent ions in polysaccharide structures, and also how bivalent ions can induce gel formation in acidic polysaccharides such as alginic acid solutions.

Structure V Calcium complexed in polysaccharides

It has been found that such interactions have dietary significance.

|

Dietary fibre from plants binds calcium in proportion to its uronic acid content. This binding by the non-cellulosic fraction of fibre reduces the availability of calcium for small-intestinal absorption, although colonic digestion of uronic acids liberates the calcium.4 The pH dependence of the binding strongly suggests the involvement of carboxylic acid groups. Where daily fibre intakes vary between 50 and 150 g, with perhaps 30–110 mmol uronic acid, the binding capacity of fibre may exceed the total intake of calcium, which may be less than 20 mmol (800 mg) per day. |

7.3.5 Interaction of polymers with solvents including water

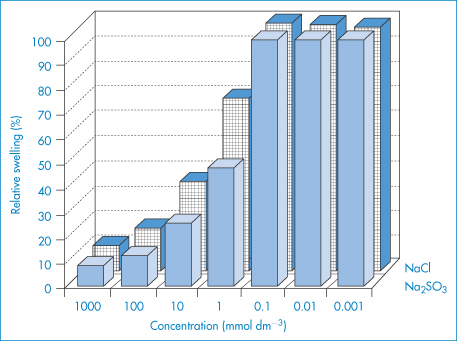

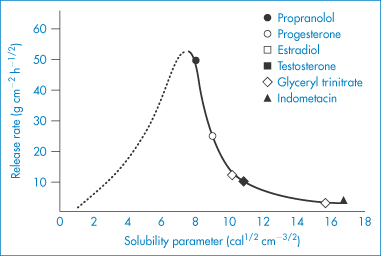

As a consequence of their size, polymers interact with solvents in a more complex fashion than do smaller crystalline solutes. A given polymer may have no saturation solubility; it usually either dissolves completely or is only swollen by a given liquid. If the polymer is crosslinked, solution cannot occur and the polymer will only swell by imbibition of liquid to form a gel. Swelling decreases as the degree of crosslinking increases. Swelling is also a function of the solubility parameter of the liquid phase, and if the polymer is ionic, swelling will be dependent on the ionic strength of the solution, as shown in Fig. 7.10 for crosslinked hyaluronic acid (HA) gels. Increasing ionic strength decreases the repulsion between the chains and allows the polymer to shrink.

Figure 7.10 Relative swelling of hyaluronic acid hydrogels in different concentrations of NaCl and Na2SO3 solutions.

Reproduced from Tomer R et al. Electrically controlled release of macromolecules from cross-linked hyaluronic acid hydrogels. J Control Release 1995;33:405. Copyright Elsevier 1995.

Highly polar polymers like poly(vinyl chloride) and some cellulose derivatives require polar liquids as solvents, in which dipole interactions or hydrogen bonding between polymer and solvent molecules occur. However, solvation does not necessarily lead to solution because the liquid, if it is to act as a solvent, must dissolve the solvated polymer. This process may be very slow because of the high viscosity of the partially solvated system.

Swelling of hydrogels and drug release

The relative mobility of a drug diffusing in the swelling hydrogel is given by the swelling interface number, Sw defined as

where ν is the velocity of the moving front, δ(t) is the thickness of the rubbery layer (the infiltration and gel layers represented in Fig. 7.7) at time t and D is the diffusion coefficient of the drug in the matrix.5 When Sw  1, Fickian drug diffusion predominates, whereas when Sw

1, Fickian drug diffusion predominates, whereas when Sw  1, zero-order release kinetics are observed. The amount of drug released from a thin slab is expressed as an exponential:

1, zero-order release kinetics are observed. The amount of drug released from a thin slab is expressed as an exponential:

n varying from − 0.5 to >1.0 where Mt /M∞ is the fraction of drug and k is a constant.

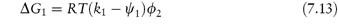

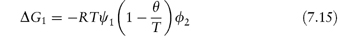

It has been seen in Chapter 6 that the use of macromolecules as dispersion stabilisers depends in part on the osmotic forces arising from the interaction of solvated polymer chains as neighbouring particles approach (see Fig. 6.7). It is thus important to know how factors such as temperature and additives affect this interaction. Flory has given the free energy of dilution (the opposite process to the concentration effect discussed in section 6.2) as

where  is the volume fraction of polymer, and k1 and ψ1 are heat and entropy parameters, respectively.

is the volume fraction of polymer, and k1 and ψ1 are heat and entropy parameters, respectively.

It is sometimes convenient to define the temperature at which a polymer of infinite molecular weight just becomes insoluble in a given solvent; this temperature is the Flory temperature or theta temperature, θ, which may also be defined by

so that substituting in equation (7.13) we obtain the relationship between ΔG1 and temperature:

ΔG1 is therefore zero at the theta temperature when deviations from ideality vanish, that is, there are no polymer–polymer or polymer–solvent interactions. When T = θ there can thus be no stabilisation as molecules will interpenetrate without net interaction and will exert no forces on each other.

Not only do most linear polysaccharides tend to form spirals in solution, but in their tendency to associate they may form double helices, as does carrageenan, for instance. Under certain conditions of concentration and temperature the double helices may associate, forming gels. Possibilities exist for complex gel formation as with carrageenan, or of xanthan gum with locust bean gum. The locust bean gum molecule can associate over part of its length with the helix of xanthan, for example, while the other part of the molecule associates with another xanthan molecule, thereby acting as a bridging agent.

The firmness or strength of gels produced by such interactions will depend on the degree of interaction of the complex with water and the properties of the bridging units.

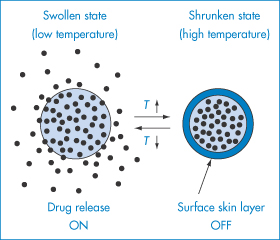

The ability to change the swelling characteristics of a polymer gel by heat, pH or application of electric current can be valuable in specialised delivery systems, as exemplified in Fig. 7.11, which shows the effect of temperature change on the swelling and de-swelling of a hydrogel, resulting in an on–off ‘switching’ mechanism.

Figure 7.11 On–off switching mechanism for drug release.

Reproduced from Yoshida R et al. Pulsatile drug delivery systems using hydrogels. Adv Drug Deliv Rev 1993;11:85. Copyright Elsevier 1993.

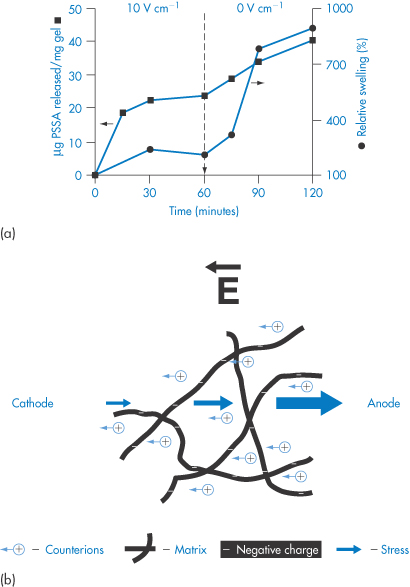

The relationship between swelling and release in an electrically responsive hydrogel is shown in Fig. 7.12. The mechanism of the current-induced change in volume of the gel is shown in Fig. 7.12b.

Figure 7.12 (a) Responsive swelling (●) and release (■) from poly(styrene sulfonic acid)-loaded hyaluronic acid hydrogels when an electric field of 10 V cm−1 was switched off. (b) The effect of an electric field on a polyelectrolyte network. The redistribution of ions causes shrinkage of the gel at the cathode and expansion at the anode.

(a) Reproduced from Tomer R et al. Electrically controlled release of macromolecules from cross-linked hyaluronic acid hydrogels. J Control Release, 1995; 33: 405. Copyright Elsevier 1995.

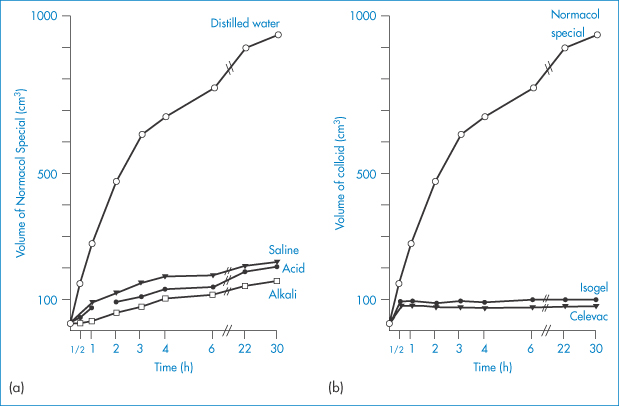

Hydrophilic polymers as bulk laxatives

The ability of carbohydrates and other macromolecules to imbibe large quantities of water is put to use both medicinally and industrially; for example, in absorbent paper and sanitary towels, incontinence pads and surgical dressings. Medically, use is made of the swelling properties in the treatment of constipation and in appetite suppression. Three properties are of importance in the in vitro evaluation of bulk laxatives:

- the volume of water absorbed in the various media

- the viscosity and texture of the gel formed

- the ability of the gel to retain water.

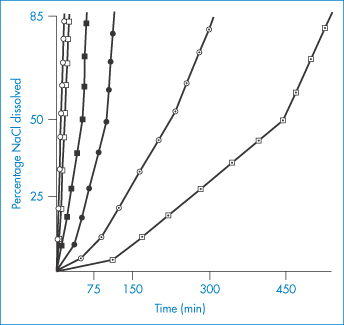

The swelling properties of a sterculia-based preparation (Normacol) in various aqueous media and a comparison of Normacol with two other agents are shown in Fig. 7.13.

Figure 7.13 (a) The volume attained by 5 g of Normacol Special in various solutions over 30 hours. (b) The volumes attained by 5 g of Normacol Special, Isogel and Celevac in distilled water.

Reproduced from Ireson JD, Leslie GB. Pharm J 1970;205:540.

|

It is desirable that colloidal bulk laxatives swell in the lower part of the small intestine and in the large intestine to cause reflex peristalsis, rather than in the stomach or duodenum; that is, they should swell in neutral rather than acidic or alkaline conditions. In artificial intestinal juice, psyllium seed gum increased in volume 5–14 times, locust bean gum 5–10 times and methylcellulose 16–30 times in 24 hours. In vivo evaluation of methylcellulose and carboxymethylcellulose suggests that they have two advantages over the natural gums. Methylcellulose is more efficient as a bulk laxative because of its greater water-retentive capacity, whereas carboxymethylcellulose gives uniform distribution through the intestinal contents. |

7.3.6 Adsorption of macromolecules

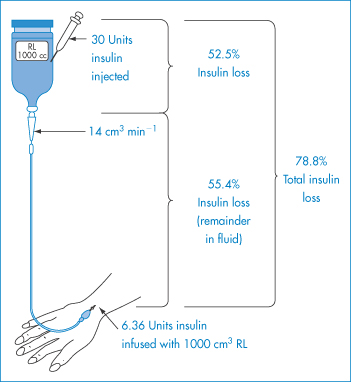

The ability of some macromolecules to adsorb at interfaces is made use of in suspension and emulsion stabilisation (see Chapter 6). Gelatin, acacia, poly(vinyl alcohol) and proteins adsorb at interfaces. Sometimes such adsorption is unwanted, as in the case of insulin adsorption on to glass infusion bottles and poly(vinyl chloride) infusion containers and tubing used in giving sets.

|

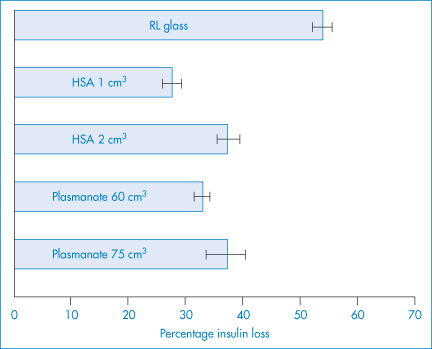

Adsorption of insulin to glass bottles and plastic intravenous (IV) tubing at slow rates of infusion is well documented. Adsorption ranges from 5% to 3.1% when 20 and 40 units respectively are added to 500 cm3 of isotonic sodium chloride solution. Plastic IV tubing adsorbed 30% of 20 units and 26% of 40 units added to the same infusion bottles (Fig. 7.14). Adsorption occurs rapidly, within 15 seconds. Addition of albumin to prevent adsorption is now common practice. The albumin adsorbs at the glass or plastic surface and presents a more polar surface to the solution, thus reducing, but not always preventing, adsorption of the insulin (Fig. 7.15). The binding is considered to be a non-specific phenomenon that may occur on other inert materials such as polyethylene and glass. |

Figure 7.14 Amounts of insulin lost by adsorption to glass bottles and plastic intravenous tubing, following injection of 30 units of insulin. The patient receives only 6.36 units.

Reproduced from Petty C, Cunningham NL. Anaesthesiology 1974;40:400.

Figure 7.15 Prevention of insulin loss via adsorption by the addition of human serum albumin (HSA) or Plasmanate to 1000 cm3 of Ringer’s lactate (RL) solution in a glass bottle. Insulin (30 units) was injected and measured at 5 minutes. Values represent means ± SEM. All HSA and Plasmanate values were significantly different from Ringer’s lactate solution control (p < 0.001).

Reproduced from Petty C, Cunningham NL. Anaesthesiology 1974;40:400.

The adsorption of macromolecules at interfaces may be the reason why molecules such as those of HA can act as biological lubricants in joint fluids (see section 7.4.11). In healthy joints only 0.5 cm3 of synovial fluid is required to provide almost perfect lubrication; in diseased joints there are sometimes faults in this lubrication system and some research has been aimed at producing synthetic substitutes for synovial fluid. Polymer solutions provide one approach as their rheological characteristics more closely approach those of the natural fluid, which is non-Newtonian.

7.4 Water-soluble polymers used in pharmacy and medicine

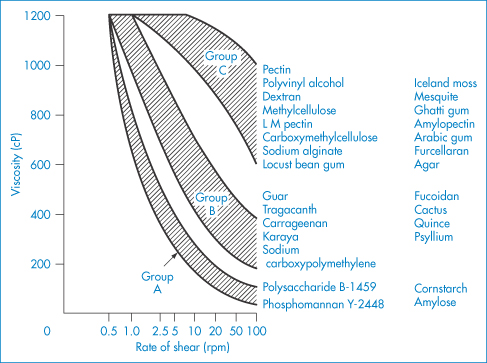

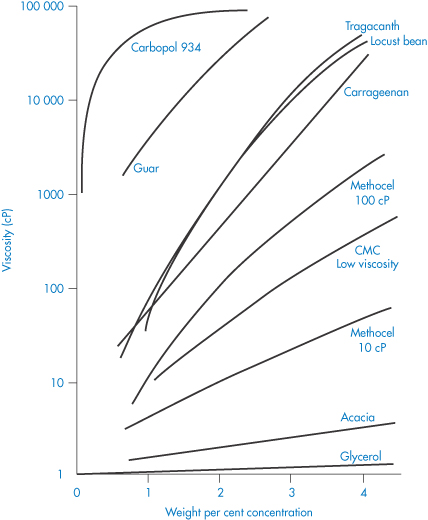

In this section the properties of some specific polymers used in pharmacy and medicine will be discussed. This cannot be an exhaustive treatment of the subject, so choice of the macromolecular material for this section has been based partly on the degree of use but partly on the generally interesting features they display. The choice of a macromolecular material for a particular pharmaceutical use is often difficult because of the diversity of properties exhibited by the materials available. Figure 7.16 illustrates how the field can be narrowed to some extent by grouping the natural and synthetic materials of interest to the formulator. This is, however, a very general guide, as the properties of individual macromolecules will, as discussed, often vary with pH, temperature, molecular weight and ionic strength. The most readily altered variable is, of course, the concentration of the macromolecule, whose effect on viscosity is illustrated for a range of compounds in Fig. 7.17. The most viscous material shown here is Carbopol 934.

Figure 7.16 Effect of shear rate on the viscosity of gum solutions grouped according to their rheological behaviour.

Modified from Szezesniak AS, Farkas EH. Objective characterization of the mouthfeel of gum solutions. J Food Sci 1962;27:381. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission.

Figure 7.17 Viscosity of solutions of some pharmaceutical polymers and gums compared with glycerol plotted as a function of concentration.

Reproduced from Martin AN et al. Rheology. Adv Pharm Sci 1964;1:1.

7.4.1 Carboxypolymethylene (Carbomer, Carbopol)

Carboxypolymethylene is used as a suspending agent in pharmaceutical preparations and as a binding agent in tablets, and it is used in the formulation of prolonged-action tablets. It is a high-molecular-weight polymer of acrylic acid, containing a high proportion of carboxyl groups. Its aqueous solutions are acidic; when neutralised the solutions become very viscous, with a maximum viscosity occuring between pH 6 and 11. Electrolytes reduce the viscosity of the system and thus high concentrations of the polymer have to be employed in vehicles where ionisable drugs are present. A carbomer gel prolongs the contact time of drugs instilled into the eye.

7.4.2 Cellulose derivatives

Cellulose itself is virtually insoluble in water, but aqueous solubility can be conferred by partial methylation or carboxymethylation of cellulose.

Ethylcellulose is an ethyl ether of cellulose containing 44–51% of ethoxyl groups. It is insoluble in water but soluble in chloroform and in alcohol. It is possible to form water-soluble grades with a lower degree of substitution.

Methylcellulose samples are prepared by heterogeneous reaction that is usually controlled to allow substitution of, on average, about one-half of the hydroxyl groups. This leads to a product in which the methylated groups are not evenly distributed throughout the chains; rather, there are regions of high density of substitution (as in structure VI) that are hydrophobic in nature, and regions of low density of substitution that are hydrophilic in nature.

Structure VI Highly methylated region of the methylcellulose chain

Methylcellulose is thus a methyl ether of cellulose containing about 29% of methoxyl groups; it is slowly soluble in water. A 2% solution of methylcellulose 4500 has a gel point of about 50°C. High concentrations of electrolytes salt out the macromolecules and increase their viscosity; eventually precipitation may occur. Low-viscosity grades are used as emulsifiers for liquid paraffin and other mineral oils. High-viscosity grades are used as thickening agents for medicated jellies and as dispersing and thickening agents in suspensions.

Since methylcelluloses are poorly soluble in cold water, preliminary use of hot water ensures wetting of all portions of the particle prior to solution in cold water. The water-soluble methylcelluloses possess the property of thermal gelation; that is, they gel on heating while the natural gums gel on cooling. Methylcellulose exists in solution as long thread-like molecules hydrated by water molecules. On heating, the water of solvation tends to be lost; the ‘lubricating’ action of the hydration layer is also lost and the molecules lock together in a gel. Gelation is reversible on cooling. Variation in the alkyl or hydroxyalkyl substitution can be a means of controlling the gel points (Table 7.4). As the methoxyl content is lowered, the temperature of gelation increases and water solubility decreases. Unlike the ionic celluloses, the non-ionic alkylcelluloses possess surface activity. As the methoxyl content is reduced, the surface and interfacial activities are also reduced, reflecting the importance of the hydrophobic moiety in determining surface activity.

Table 7.4 Gel point and surface activity of cellulose derivatives

Derivative | Percentage ‒OCH3 | Percentage ‒OCH2CH(OH)CH3 | Gel pointa (°C) | Surface tensionb (mN m−1) | Interfacial tensionc (mN m−1) |

Methocel MC | 27.5–3.2 | – | 50–55 | 47–53 | 19–23 |

Methocel 60HG | 28–30 | 7–12 | 55–60 | 44–50 | 18–19 |

Methocel 65HG | 27–30 | 4–7.5 | 60–65 | – | – |

Methocel 70HG | 24–27 | 4–8 | 66–72 | – | – |

Methocel 90HG | 22–25 | 6–12 | 85 | 50–56 | 26–28 |

Reproduced from Windover FE. In: Davidson RL, Sittig M (eds) Water Soluble Resins. New York: Reinhold; 1962: 52ff.

a2% solution.

bSurface tension at 25°C.

cInterfacial tension versus paraffin oil at 25°C.

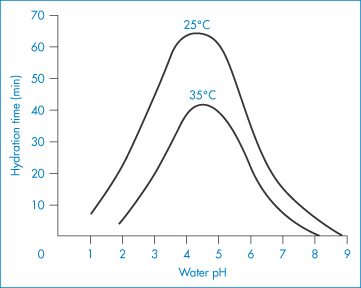

Ethylhydroxyethylcellulose (EHMC) is an ether of cellulose with both ethyl and hydroxyethyl substituents attached via ether linkages to the anhydroglucose rings. It swells in water to form a clear, viscous colloidal solution. Preparation of solutions of cellulose derivatives requires hydration of the macromolecules, the rate of which is a function of both temperature and pH, as shown in the example in Fig. 7.18.

Figure 7.18 Effect of pH and temperature on the hydration time of fast-dissolving grades of hydroxyethylcellulose.

Reproduced with permission from Whistler RL (ed.) Industrial Gums, 2nd edn. New York: Academic Press; 1973.

Hydroxyethylcellulose (HEC) is soluble in hot and cold water but does not gel. It has been used in ophthalmic solutions. More widely used for the latter, however, is HPMC (hypromellose), which is a mixed ether of cellulose containing 27–30% of ‒OCH3 groups and 4–7.5% of ‒OC3H6OH groups. It forms a viscous colloidal solution. There are various pharmaceutical grades. For example, hypromellose 20 is a 2% solution that has a viscosity between 15 and 25 cSt (centistokes) at 20°C; the viscosity of a 2% hypromellose 15000 solution lies between 12 000 and 18 000 cSt. Hypromellose prolongs the action of medicated eye drops and is employed as an artificial tear fluid.

Sodium carboxymethylcellulose (NaCMC) is soluble in water at all temperatures. Because of the carboxylate group, its mucilages are more sensitive to change in pH than are those of methylcellulose. The viscosity of an NaCMC mucilage is decreased markedly below pH 5 or above pH 10.

7.4.3 Natural polymers: gums and mucilages

Gum arabic (acacia) has been used traditionally in pharmacy as an emulsifier. It is a polyelectrolyte whose solutions are highly viscous owing to the branched structure of the macromolecular chains; its adhesive properties are also believed to be due to, or in some way related to, this branched structure. Molecular weights between 200 000 and 250 000 Da (Mn) have been determined by osmotic pressure, values between 250 000 and 3 × 106 Da by sedimentation and diffusion, and values of 106 Da by light-scattering measurements which also point to the shape of the molecules as short stiff spirals with numerous side-chains. Arabic acid prepared from commercial gum arabic by precipitation is a moderately strong acid whose aqueous solutions have a pH of 2.2–2.7.

Whereas most gums are very viscous in aqueous solution, gum arabic is unusual in that, being extremely soluble, it can form solutions over a wide range of concentrations up to about 37% at 25°C. The marked variation in viscosity means that the gum arabic molecules must be flexible, with the ionic acid carboxyl groups distributed along the chain. At low pH the carboxyl groups are un-ionised. On increase of pH the carboxyl groups become progressively ionised and the folded chains expand owing to repulsion between the charged groups, causing an increase in viscosity. On addition of NaOH to the system the viscosity falls again as the concentration of counterion (Na+) increases and effectively shields the acidic groups. The molecule then folds on itself. Similar falls in viscosity are exhibited on addition of sodium chloride. The effect of salt addition to the gum at fixed pH reflects the decrease in effective charge on the molecules of gum with resultant contraction and reduction in viscosity.

The gum arabic molecule is, in addition, surface-active: a 4% solution at 30°C has a surface tension of 63.2 mN m−1. Addition of electrolytes makes the molecule more surface-active either by causing a change in conformation of the molecule at the interface, allowing closer packing, or by increasing the hydrophobicity of the molecule. It is an effective emulsifier, the stabilisation of the emulsion being dependent mainly on the coherence and elasticity of the interfacial film, which is by no means monomolecular.

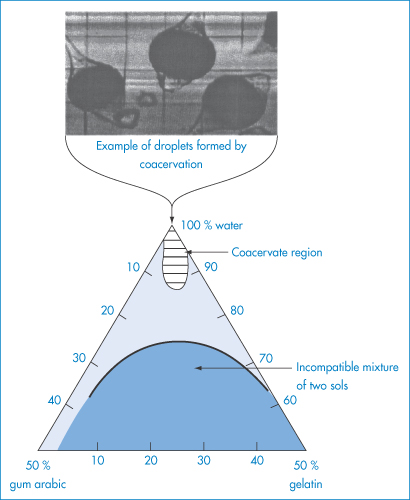

Gum arabic is incompatible with several phenolic compounds; under suitable conditions it forms coacervates (see section 7.6.3) with gelatin and positively charged polyelectrolytes.

Gum tragacanth partially dissolves in water; the soluble portion is called tragacanthin and this can be purified by precipitation from water with acetone or alcohol. Tragacanthin is a highly viscous polyelectrolyte with a molecular weight of 800 000 Da (as determined by sedimentation measurements). It is one of the most widely used natural emulsifiers and thickeners. As its molecules have an elongated shape, its solutions have a high viscosity which, as with gum arabic, is dependent on pH. The maximum viscosity occurs at pH 8 initially, but because of ageing effects the maximum stable viscosity is near pH 5.

It is an effective suspending agent for pharmaceuticals and is used in conjunction with acacia as an emulsifier, the tragacanth imparting a high structural viscosity while the gum arabic adsorbs at the oil–water interface.

|

Tragacanth is also used in spermicidal jellies, acting both by immobilising spermatozoa and acting as a viscous barrier to spermatozoa. It is also used as an excipient in contraceptive preparations which contain chemical contraceptive molecules where its physical effect on spermatozoa reinforces the direct chemical action of the contraceptive agents. |

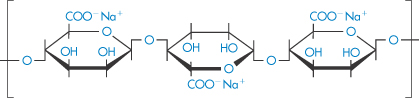

Alginates. Although the solutions of alginate are very viscous and set on addition of acid or calcium salts, they are less readily gelled than pectin and are used chiefly as stabilisers and thickening agents. Propylene glycol alginate does not precipitate in acid and, as it is non-toxic, is widely used as a stabiliser for foodstuffs. The molecules are highly asymmetric, with molecular weights in the range 47 000–370 000 Da. Sodium alginate has the structure given in VII.

Structure VII Sodium alginate

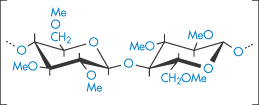

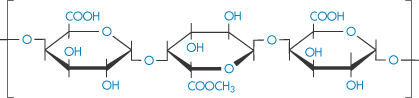

Pectin is a purified carbohydrate product from extracts of the rind of citrus fruits and consists of partially methoxylated polygalacturonic acid (VIII). It has remarkable gelling qualities but is also used therapeutically, often with kaolin, in the treatment of diarrhoea. It has been established that the longer the pectin chains, the greater its capacity for gel formation. The presence of inorganic cations and the degree of esterification of the carboxyl groups are important factors; in the case of calcium pectate gel it can be assumed that the calcium or indeed other polyvalent cations can interlink the chains by binding through COO−…Ca2+…−OOC interactions. Thus a high degree of esterification will disfavour gelation in this case. In the absence of inorganic cations, however, a high degree of esterification aids gelation, suggesting that hydrophobic interactions cause the chains to associate.

Structure VIII Partially methylated chain of poly(galacturonic acid) of pectin

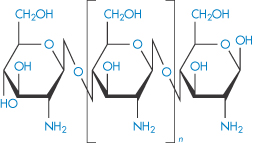

7.4.4 Chitosan

Chitosan is a polymer obtained by the deacetylation of chitin, one of the most abundant polysaccharides. Chitosan, or poly[α-(1,4)-2-amino-2-deoxy-D-glucopyranose], has the structure (IX). As might be expected, the degree of deacetylation has a significant effect on the solubility and rheological properties of the polymer. At low pH, the polymer is soluble, with the sol–gel transition occurring at approximately pH 7. Chitosan also has film-forming abilities and its gel- and matrix-forming abilities make it useful for solid-dosage forms, such as granules or microparticles.6 The molecular weight, crystallinity and degree of deacetylation are all factors that can be varied to control the release rates from chitosan-based granules.

Structure IX The chemical structure of chitosan. The amine groups on the polymer have a pKa in the range 5.5–6.5, depending on the source of the polymer

7.4.5 Dextran

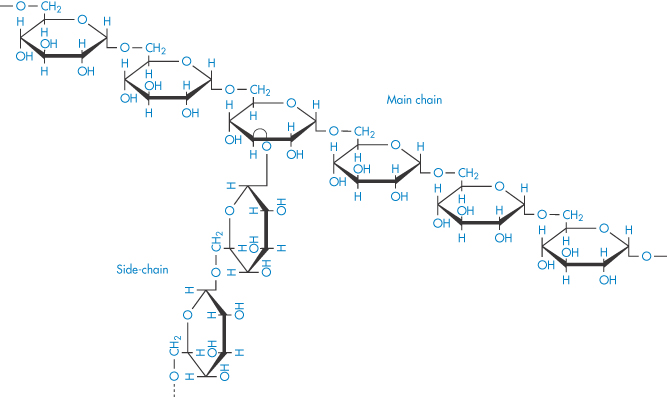

Certain fractions of partially hydrolysed dextran are used as plasma substitutes or ‘expanders’. Certain strains of Leuconostoc meserentoides are cultivated to synthesise dextran (X), which is a polymer of anhydroglucose, linked through α-1,6 glucosidic linkages. The chains are branched; on the average, one branch occurs for every 10–12 glucose residues. The intrinsic viscosity [ ] is related to M by the relationship

] is related to M by the relationship

in the molecular weight range 20 000–200 000 Da. The dextrans produced by fermentation are hydrolysed and fractionated to give a range of products suitable for injection. Dextran, being a hydrophilic colloid, exerts an osmotic pressure comparable to that of plasma and it is thus used to restore or maintain blood volume. Other substances that have been used in a similar way include hydroxyethyl starch, polyvinylpyrrolidone (PVP) and gelatin.

Structure X Dextran

|

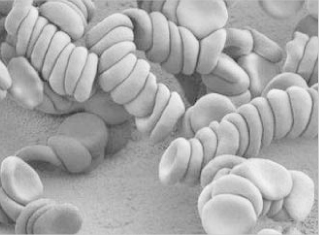

Dextran injections are sterile solutions of dextran with weight-average molecular weights of about 40 000–110 000 Da. Dextrans with a molecular weight of about 50 000 Da or less are excreted in the urine within 48 hours of injection. Dextran molecules with higher molecular weights disappear more slowly from the blood stream and are temporarily stored in the reticuloendothelial system. Dextran 70 (70 000 Da) and Dextran 110 (110 000 Da) are used to maintain blood volume, and Dextran 40 is used primarily to prevent intravascular aggregation of blood cells and for assisting capillary blood flow. This latter effect is the result of dextran adsorption and stabilisation of the erythrocyte suspensions. If the higher-molecular-weight fractions exceed about 1% concentration in the blood, rouleaux (see photomicrograph) tend to form.

|

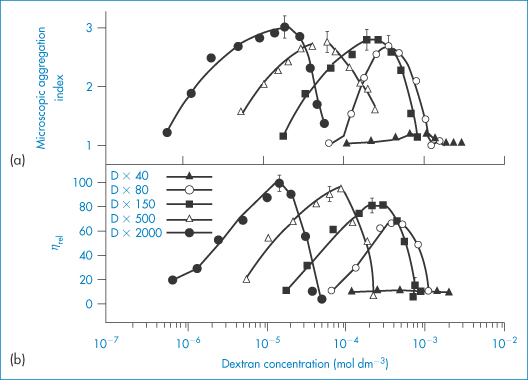

The sensitivity of blood to the concentration and molecular weight of dextran is clearly seen in Fig. 7.19, where aggregation and relative viscosity of red-cell suspensions are shown in the presence of varying amounts of five different dextrans. Molecular weight control is thus important and may be exercised by measurement of intrinsic viscosity, [ ].

].

Figure 7.19 Variation of indices of red-cell aggregation with the concentration of five dextran fractions of different molecular weight: (a) microscopic aggregation index; (b) relative viscosity at a shear rate of 0.1 s−1. Note that the maximum of each curve (that is, maximum aggregation of the red cells) corresponds to a well-defined concentration of a particular dextran fraction. Maxima in both indices of aggregation of red cells occur at about the same concentration of dextran fraction.

Reproduced with permission from Chien S. Bib Anat Basel 1973;11:244.

7.4.6 Iron–dextran complexes

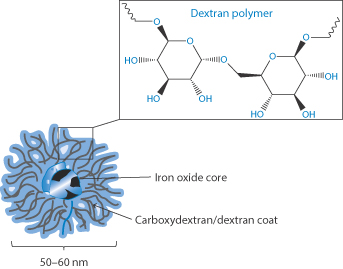

Iron–dextran complexes are soluble, non-ionic and suitable for injection for the treatment of anaemia (Fig. 7.20); the complex is stable on storage in the pH range 4–11.

Figure 7.20 Conceptual drawing of an iron–dextran complex, showing the iron oxide core surrounded by a corona of dextran and carboxydextran molecules.

After Abdollah MRA et al. Faraday Disc 2014; 75:41–58; see also London E. J Pharm Sci 2004;93:1838–1846.

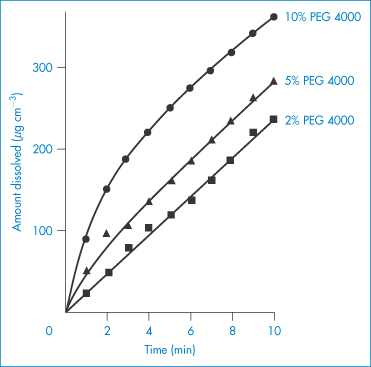

7.4.7 Polyvinylpyrrolidone

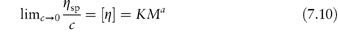

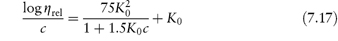

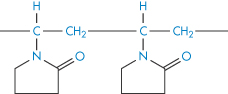

PVP is used as a suspending and dispersing agent, as a tablet-binding and granulating agent, and as a vehicle for drugs such as penicillin, cortisone, procaine and insulin to delay their absorption and prolong their action. It forms hard films that are utilised in film-coating processes. Chemically it is a homopolymer of N-vinylpyrrolidone (XI). It is available in a number of grades, designated by numbers ranging from K15 to K90. The K values represent a function of the mean molecular weight, and can be calculated from

where c = concentration in grams per 100 cm3 and  rel is the viscosity relative to the solvent. K = 1000K0. Viscosity is essentially independent of pH over the range 0–10 and aqueous solutions exhibit a high tolerance for many inorganic salts. Its wide solubility in organic solvents is unusual. The viscosity of a range of aqueous solutions of PVP is shown in Fig. 7.21.

rel is the viscosity relative to the solvent. K = 1000K0. Viscosity is essentially independent of pH over the range 0–10 and aqueous solutions exhibit a high tolerance for many inorganic salts. Its wide solubility in organic solvents is unusual. The viscosity of a range of aqueous solutions of PVP is shown in Fig. 7.21.

Structure XI Polyvinylpyrrolidone

Figure 7.21 Viscosity of polyvinylpyrrolidone (PVP) solutions as a function of molecular weight (PVP K15 (mol wt 40 000 Da) to PVP K90 (mol wt 700 000 Da)) and concentration of the polymer in water.

Reproduced from Azorlosa JL, Martinelli AJ. In: Davidson RL, Sittig M (eds) Water Soluble Resins. New York: Reinhold; 1962.

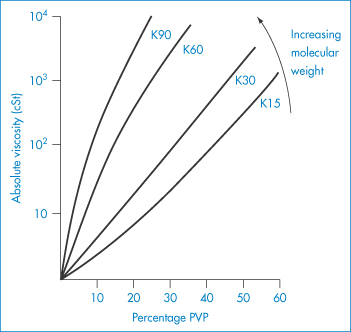

PVP forms molecular adducts with many substances. Soluble complexes, called iodophors, are formed with iodine: the solubility of iodine is increased from 0.034% in water at 25°C to 0.58% by 1% PVP. The resulting iodophor retains the germicidal properties of iodine. It is thought that the iodine is held in a PVP helix in solution. The influence of two samples of PVP on the solubility of testosterone is shown in Fig. 7.22. The PVP correspondingly increases the rate of solution of the steroid from solid dispersions.

Figure 7.22 The influence of PVP 11500 and PVP 40000 on the aqueous solubility of testosterone at 37°C.

Reproduced from Hoelgaard A, Muller N. Arch Pharm Chem 1975;3:34.

7.4.8 Polyoxyethylene glycols (macrogols)

Poloxyethyelene glycols are widely used in pharmaceutical formulations not only as solvents and bases for ointments and suppositories but also as molecules which can determine the lifetime of nanoparticles in the blood by adsorbing on to particle hydrophobic surfaces to prevent opsonin adsorption (see Chapter 14).

Macrogols (polyoxyethylene glycols (PEGs), XII) are liquid over the molecular weight range 200–700 Da; the liquid members and semisolid members of the series are hygroscopic. Macrogol 200 has a hygroscopicity 70% of that of glycerol, but this decreases with molecular weight: the comparable value for Macrogol 1540 is only 30%. They are used as solvents for drugs such as hydrocortisone. The macrogols are incompatible with phenols and can reduce the antimicrobial activity of other preservatives. Higher-molecular-weight PEGs are more effective on a molecular basis as complexing agents. Up to four phenol molecules bind to each PEG molecule; the complex formed is of the donor–acceptor type. The semisolid and waxy members of the series may be used as suppository bases; in such cases their potential to interact with medicaments must be borne in mind.

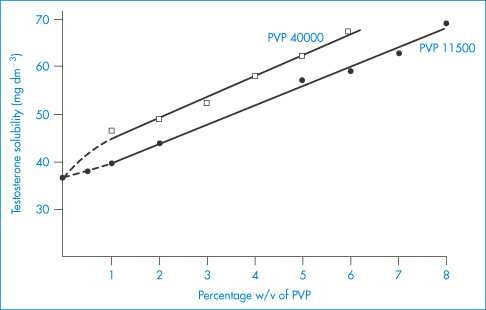

Structure XII Polyoxyethylene glycol

Use of PEGs, and other hydrophilic polymers, in high concentrations in formulations can influence the behaviour of drugs even when the drug is present as a physical mixture with the polymer. For example, combination of PEG 4000 with sulfathiazole increases the solution rate of sulfonamides (Fig. 7.23). Probable mechanisms include an increase in drug solubility or increased wetting of the drug surrounded by the hydrophilic polymer. Apart from these uses, the PEGs have turned out to be one of the most versatile water-soluble polymers. They have been successful in modifying the behaviour of proteins, including monoclonal antibodies, in solution and in the circulation after being grafted to these molecules. The PEGs also prolong the circulation time of particulate delivery systems such as liposomes and nanoparticles through their adsorption or incorporation into the surface of these carriers, preventing the adsorption of opsonins and reducing uptake by the liver and spleen, as discussed in Chapter 12.

Figure 7.23 Dissolution rates of sulfathiazole (Form I)–polyethylene glycol 4000 physical mixtures.

Reproduced from Niazi S. Effect of polyethylene glycol 4000 on dissolution properties of sulfathiazole polymorphs. J Pharm Sci 1976;65:302. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission.

7.4.9 Bioadhesivity of water-soluble polymers

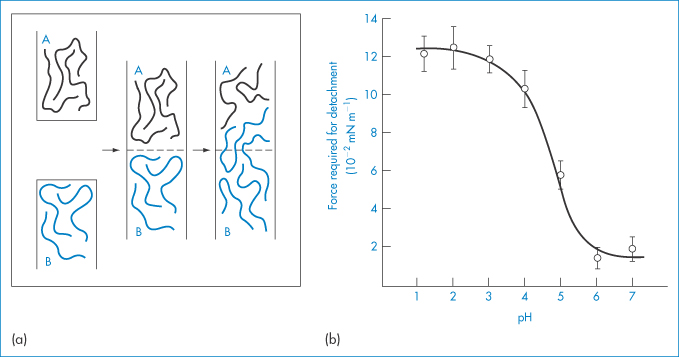

Adhesion between a surface of a hydrophilic polymer, or a surface to which a hydrophilic polymer has been grafted or adsorbed, and a biological surface arises from interactions between the polymer chains and the macromolecules on the mucosal surface. From Fig. 7.24a it is clear that to achieve maximum adhesion there should be maximum interaction between the polymer chains of the bioadhesive (A) and the mucus (B). The charge on the molecules will be important, and for two anionic polymers maximum interaction will occur when they are not charged. Penetration and association must be balanced. Table 7.5 shows the adhesive performance of a range of polymers, many of which have been discussed in this chapter. Of these, two classes have been approved by the US Food and Drug Administration: anionic poly(acrylic acid) (carbophil) derivatives and the cationic chitosans. Polycarbophil and carbomer (Carbopol 934P) have pKa values of about 4.5 and display maximum mucoadhesivity at pH values where they are mostly undissociated7 (Fig. 7.24b).

Figure 7.24 (a) Schematic representation of two phases, adhesive (A) and mucus (B), which adhere owing to chain adsorption and consecutive chain entanglement during mucoadhesion. (b) Effect of pH on in vitro bioadhesion of polycarbophil to rabbit gastric tissue.

(a) Reproduced from Peppas NA, Mikos AG. In: Gurney R, Junginger HE (eds) Bioadhesion. Stuttgart: Wiss. Verlagsgesellschaft; 1990. Copyright Elsevier 1990.

(b) From reference 7.

Table 7.5 Some representative mucoadhesives and their relative mucoadhesivities

Substance | Adhesive performance |

Carboxymethylcellulose | Excellent |

Carbopol | Excellent |

Carbopol and hydroxypropylmethylcellulose | Good |

Carbopol base with white petrolatum/hydrophilic petrolatum | Fair |

Carbopol 934 and EX 55 | Good |

Poly(methyl methacrylate) | Excellent |

Polyacrylamide | Good |

Poly(acrylic acid) | Excellent |

Polycarbophil | Excellent |

Homopolymers and copolymers of acrylic acid and butyl acrylate | Good |

Gelatin | Fair |

Sodium alginate | Excellent |

Dextran | Good |

Pectin | Poor |

Acacia | Poor |

Povidone | Poor |

Poly(acrylic acid) crosslinked with sucrose | Fair |

7.4.10 Viscous solutions and disorders of the eye

Anterior-chamber injections (intracameral injections)

Hypotony is defined as an intraocular pressure of 5 mmHg or less. Low intraocular pressure can adversely impact the eye in many ways, including causing accelerated cataract formation, maculopathy and discomfort.

Sodium hyaluronate, chondroitin sulfate and methylcellulose have been compared for maintaining the form of the anterior chamber of the eye in cases of hypotony. The rheological characteristics of the polymers used in the anterior chamber are key to success. Pseudoplastic fluids are ideal for maintaining the chamber form since they are more viscous at rest. Sodium hyaluronate and methylcellulose are pseudoplastic, while chondroitin sulfate displays Newtonian flow properties.

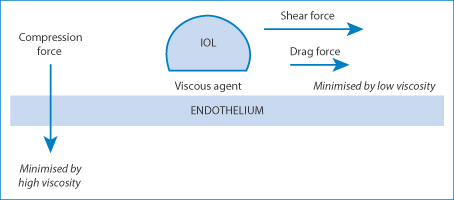

Figure 7.25 A diagram of the forces on an intraocular lens (IOL). The applied force on the lens is represented by two vectors: the compression force and the shear force. High viscosity transmits more of the shear force to the endothelial surface. The compression force is minimised by a high viscosity (note the similarity to synovial fluid) and the drag force is minimised by low viscosity.

High viscosity is critical when the agent is applied in a thick layer to prevent mechanical damage to the corneal epithelium when an intraocular lens is drawn across the endothelium. Compression and shear are responsible for the damage8: thin layers of highly viscous HA convey the shear forces to the endothelium, whereas thick layers provide a physical barrier to compression, as can be seen in Fig. 7.25. Clearly there are analogies to synovial fluid here.

Optiflex is one ophthalmic product containing sodium hyaluronate with a molecular weight of 4 × 106 Da in a sterile isotonic vehicle. When injected through a cannula it becomes less viscous, but it regains its viscosity in the anterior chamber of the eye. It is used for lubrication and protection of cells and tissue during surgical procedures.

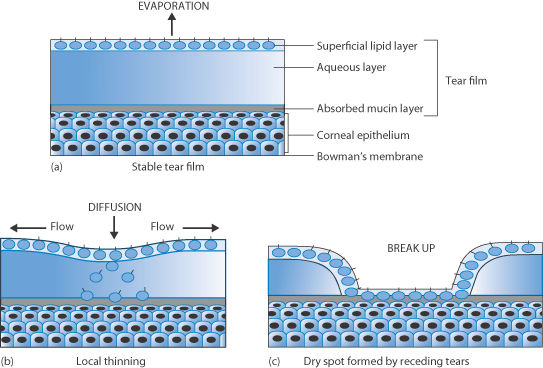

Dry eye

In some patients, the supply of tear fluid (as discussed in Chapter 9), which comprises a largely aqueous solution containing protein, lipids and enzymes, is impaired. Tears spread over the surface of the cornea, which is hydrophobic. Tear films thin and break but the fluid is replenished by blinking. The film break-up time is variable but is more rapid in patients suffering from dry-eye syndrome. The tears contain phospholipids, which act as a surfactant, lowering the surface tension of the fluid and allowing spreading. The thin lipid layer on the surface of the tear film (like most lipid monolayers) also slows down evaporation of the aqueous medium beneath. Dry eye9 (xerophthalmia*; Sjögren’s syndrome) is caused when the tear film thins to such an extent that it ruptures, exposing the corneal surface to the air, as shown schematically in Figure 7.26. Drying out of patches on the corneal surface follows. This can be painful and must be avoided. Evaporation over 5–10 minutes can actually eliminate the tear film completely.10

Figure 7.26 Schematic of (a) the effect of the lipid layer reducing evaporation of tear fluid; (b) the beginning of the thinning process; and (c) the eventual separation of the tear liquid, inducing the formation of dry spots on the cornea.

Artificial tear fluids may replace the natural tear fluid with varying degrees of similitude. Most aim for formulations that have an appropriate viscosity, but these do not necessarily possess identical rheological properties to those of natural tear fluids. HPMC is a component of many commercial replacement or ‘artificial’ tear products, as are the water-soluble macromolecules NaCMC (carmellose), poly(vinyl alcohol) and PVP.

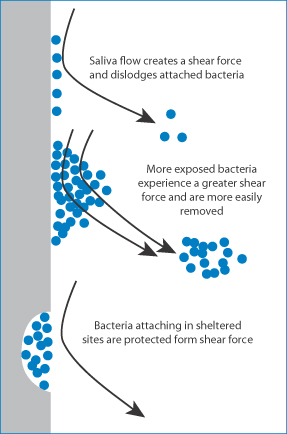

Xerostomia

Another syndrome that requires replacement or supplementation of a natural fluid with an artificial substance is xerostomia (‘dry mouth’). Normal saliva function and control are compromised in this condition. Saliva is a clear, usually alkaline and somewhat viscous secretion from the parotid, submaxillary, sublingual and smaller mucous glands of the mouth. In some cases xerostomia is caused by medication, especially by anticholinergics. Chemotherapeutic agents can also have a direct effect on salivary glands, reducing saliva output. Saliva consists primarily of water but contains enzymes and other proteins and electrolytes. It has a surface tension of around 58 mN m–1. Saliva is essential for the normal ‘feel’ of the mouth and it assists lubrication, possesses antimicrobial activity and aids mucosal integrity. Saliva provides protection by constantly flushing non-adhered microbes, their toxins and nutrients from the mouth. It has also been suggested that the flow of saliva detaches adsorbed microbes from the teeth or prevents their adhesion, as shown in Fig. 7.27 Saliva contains a wide spectrum of agents such as lactoferrin, lysozyme, histatins, cystatins, mucins, agglutinins, secretory leukocyte proteinase inhibitor, tissue inhibitors of proteinases, chitinase, peroxidases and calprotectin.

Figure 7.27 Diagram of the effect of salivary flow in the normal mouth, dislodging bacteria adsorbed on teeth. Different situations are shown, with more exposed bacteria and bacteria in sheltered sites, such as crevices.

Dry mouth can be treated with artificial saliva, although these solutions, as can be imagined from the list of components of natural saliva, seldom truly mimic the properties of the natural lubricant and wetting material. Designed to behave as far as possible like natural saliva, commercially available artificial salivas mostly contain carboxymethylcellulose and hydroxyethylcellulose to increase viscosity. The rheological properties of saliva are, as one can imagine, quite complex, but these polymer additives do at least increase the residence time of the fluid. However, gel formulations that can prolong contact between the fluid and the oral mucosa are sometimes preferred.

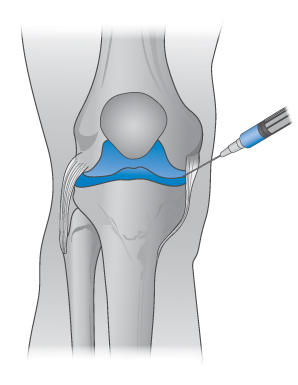

7.4.11 Intra-articular hyaluronic acid

Synovial fluid is rheopexic – that is, stress increases with time in steady shear (see section 6.3). This is thought to be the result of protein aggregation with time and the influence of stress on the process. It is suggested11 that there is a connection between the observed rheopexy and the remarkable lubrication properties of synovial fluid; one can envisage that the fluid that exists between two bony surfaces becomes more effective in ‘cushioning’ the contacts as its viscosity increases with the forces placed on it.

Products containing HA, such as Hyalgan, Artzal, Synvisc, Suplasyn, Hyalart and Orthovisc, have been developed for administration into the synovial space of joints to enhance the activity of the natural synovial fluid. The perception that higher-molecular-weight HA is superior to lower-molecular-weight species is based on the suggestion that high-molecular-weight HA normalises synovial fluid and results in effective joint lubrication. Higher-molecular-weight HAs are chemically crosslinked forms and are claimed to have a greater residence time in the joints.12 In vivo, HA with a higher viscosity has been found to be more effective in lubricating joints.13

There is some controversy about modes of action. It has also been suggested that viscoelasticity does not in fact form the foundation of the beneficial properties of these injections.14 This point is added because explanations of the behaviour of complex systems are fraught with confounding factors. One must, however, speculate from a reasoned base when necessary. It is highly reasonable to conclude that one of the important properties of hyaluronan and hyaluronan solutions is their pseudoplastic behaviour. These then serve as lubricants when joint movements are slow and as shock absorbers when movements are fast15 (Fig. 7.28).

Figure 7.28 The site of administration of intra-articular injections of agents such as hyaluronic acid to lubricate the movement of the joints, as discussed in the text.

7.4.12 Polymer crystallinity

Polymers form perfect crystals with difficulty, simply because of the low probability of arranging the chains in a regular fashion, especially at high molecular weights. Advantage can be taken of defects in crystals in the preparation of microcrystals. Microcrystalline cellulose (Avicel) is prepared by disruption of larger crystals. It is used as a tablet excipient and as a binder-disintegrant. Dispersed in water, it forms colloidal gels, and it can be used to form heat-stable oil-in-water (o/w) emulsions. Spheroids of microcrystalline cellulose with accurately controlled diameters can be prepared and drugs can be incorporated during preparation. The concept of crystallinity is potentially important when considering polymer membranes, as discussed below.

7.5 Water-insoluble polymers and polymer membranes

In defining the properties of polymers for drug formulation, certain characteristics are important. Obviously molecular weight and molecular weight distribution must be known, as these affect solvent penetration and crystallinity. The functionality of the polymer is best described by a series of parameters such as

- glass transition temperature, Tg

- tensile strength

- diffusion coefficient

- hardness (crystallinity)

- solubility.

Crystallinity defines several features of polymers: rigidity, fluidity, the resistance to diffusion of small molecules in the polymer, and degradation.

In hydrogels Tg can be measured and is a measure of polymer structure, crosslinking density, solvent content and polymer–solvent interactions, as can be seen from Table 7.6.

Table 7.6 Effect of hydrogel structure and characteristics on Tg

Feature | Effect on Tg |

Presence of flexible groups in main chain | ↓ |

Bulky, inflexible side-chains | ↑ |

Flexible side-chains | ↓ |

Increase in main-chain polarity | ↑ |

Increase in crosslinking | ↑ |

Plasticiser content | ↓ |

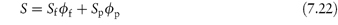

7.5.1 Permeability of polymers

Hydrophobic polymers also play an important role in pharmacy. When these materials are used as membranes, containers or tubing material, their surfaces may come into contact with solutions. The surfaces of insoluble polymers are not as inert as might be thought. The interaction of drugs and preservatives with plastics depends on the structure of the polymer and on the affinity of the compound for the plastic. The latter is determined by the degree of crystallinity of the polymer, as permeability is a function of the degree of amorphous content of the polymer. The crystalline regions of the solid polymer present an impenetrable barrier to the movement of most molecules. Diffusing molecules thus have to circumnavigate the crystalline islands, which act as obstructions. The greater the volume fraction of crystalline material ( ), the slower the movement of molecules.

), the slower the movement of molecules.

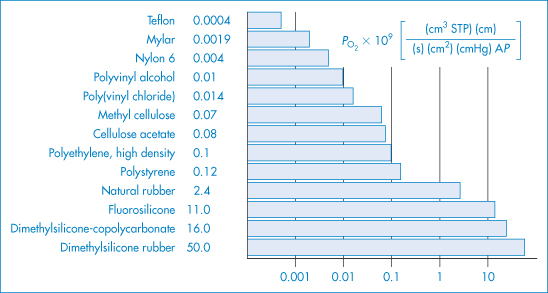

Diffusion

Diffusion in a non-porous solid polymer is of course a more difficult process than in a fluid because of the necessity for the movement of polymer chains to allow passage of the drug molecule, and it is therefore slower. The equation that governs the process is Fick’s first law (see section 2.6, equation 2.63):

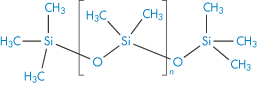

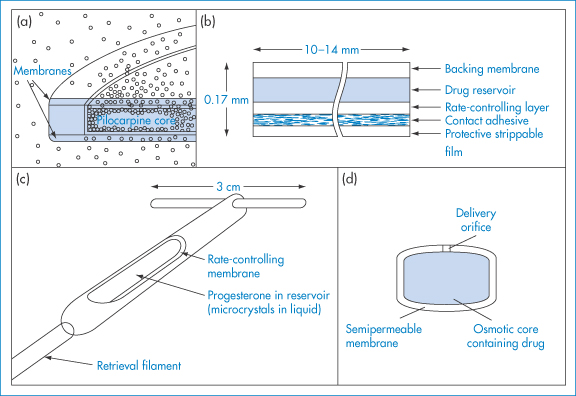

where J is the flux, D is the diffusion coefficient of the drug in the membrane and dc/dx is the concentration gradient across the membrane. If the membrane is of thickness l, and Δc represents the difference in solution concentration of drug at the two faces of membrane,