OUTLINE

Desirable Properties of Emulsifying Agents

Classification and Characteristics of Surfactants and Emulsifying Agents

I. DEFINITIONS

A. Surface-active agents, also called surfactants, are molecules or ions that are adsorbed at interfaces (1,2).

1. The molecular structure of these substances is composed of two parts: a hydrophilic (water-loving) portion, which orients itself toward water or other relatively polar liquids or solids, and a hydrophobic (water-hating) or lipophilic (oil-loving) part, which orients itself toward oil or other nonpolar solids, liquids, or gas (e.g., air).

2. Surfactants orient themselves at interfaces so as to reduce the interfacial free energy produced by the presence of the interface (2). They lower the surface tension between a liquid and a gas (e.g., air) or the interfacial tension between two liquids.

3. Surfactants can function as wetting agents, detergents, foaming agents, dispersing agents, solubilizers, and emulsifying agents.

Note: A detailed discussion of interfacial phenomena is beyond the scope of this text. For more information on this subject refer to a book on physical pharmacy (1) or the chapters on interfacial phenomena, colloidal dispersions, and coarse dispersions in Remington’s The Science and Practice of Pharmacy (2–4).

B. An emulsifying agent is a compound that concentrates at the interface of two immiscible phases, usually an oil and water. It lowers the interfacial free energy, reduces the interfacial tension between the phases, and forms a film or barrier around the droplets of the immiscible, discontinuous phase as they are formed, preventing the coalescence of the droplets.

A discussion of the emulsification process and of liquid emulsions can be found in Chapter 29, Liquid Emulsions. Semisolid emulsions, also known as creams, are described in Chapters 23, Ointment Bases, and Chapter 30, Semisolids: Ointments, Creams, Gels, Pastes, and Collodions.

II. DESIRABLE PROPERTIES OF EMULSIFYING AGENTS

A. Molecular structure

1. Although emulsifying agents must contain both hydrophilic and lipophilic parts, neither portion may be too strongly dominant (2,5). If the hydrophilic part of the molecule is completely dominant, the substance does not concentrate at the water–oil interface; it remains dissolved in the water phase. By the same token, if the lipophilic portion is too strong, the substance remains dissolved in the oil. A good emulsifier should have a reasonable balance between its hydrophilic and lipophilic groups.

2. As a general rule, emulsifying agents in which the hydrophilic groups are relatively dominant produce oil-in-water (o/w) emulsions; those in which the lipophilic groups are strongest favor the production of water-in-oil (w/o) emulsions; and those with nearly equal balance may give either type, depending on the circumstances (5). The examples below illustrate.

a. In the soap sodium stearate, the hydrophilic group—COO−Na+ is somewhat dominant over the lipophilic hydrocarbon chain C17H35—. As a result, sodium stearate is soluble in water and insoluble in oil. It does possess sufficient balance between the groups so that it concentrates at the oil–water interface and it produces o/w emulsions (6).

b. In contrast, calcium stearate contains two long hydrocarbon chains, rather than one, so that the lipophilic groups dominate. Calcium stearate is insoluble in water and soluble in oil and promotes the formation of w/o emulsions (5).

c. In both cases, the ionic portion is required. If a substance such as an acid is added to an emulsion stabilized by one of these emulsifiers, the equilibrium for the reaction R-COO−  R-COOH shifts to the right. The un-ionized form now predominates; the required hydrophilic-lipophilic balance is destroyed and the emulsifier leaves the water–oil interface and dissolves in the oil.

R-COOH shifts to the right. The un-ionized form now predominates; the required hydrophilic-lipophilic balance is destroyed and the emulsifier leaves the water–oil interface and dissolves in the oil.

B. The emulsifier must produce a stable film at the interface.

1. Some surface-active agents are capable of producing emulsions, but the emulsions separate on standing or storage because the surfactant is incapable of producing stable, strong barriers to prevent the coalescence of the dispersed droplets (5).

2. Agents such as these may be useful if combined with a second substance that acts as a stabilizer. The surfactant is then referred to as the primary emulsifying agent and the stabilizer as the secondary or auxiliary emulsifier (5). An example of such a system is the use of the primary emulsifier sodium lauryl sulfate with the auxiliary emulsifier stearyl alcohol in Hydrophilic Ointment USP (6).

C. The emulsifying agent should be stable to chemical degradation.

D. The emulsifying agent should be reasonably inert and should not interact chemically with any of the other ingredients in the formulation.

E. If the emulsifier is liable to microbiologic attack, adequate precautions must be taken.

1. In the emulsion section of USP Chapter 〈1151〉 Pharmaceutical Dosage Forms, it is stated that all emulsions require the addition of a suitable preservative because the water phase is vulnerable to the growth of microorganisms (7).

2. Other possible precautions when emulsifiers favor the growth of microorganisms include the use of refrigeration and short beyond-use datings.

F. The substance should be nontoxic and nonirritating to skin or mucous membranes.

G. Depending on its use, it should be relatively odorless, tasteless, and colorless.

H. It should have a reasonable cost.

III. CLASSIFICATION AND CHARACTERISTICS OF SURFACTANTS AND EMULSIFYING AGENTS

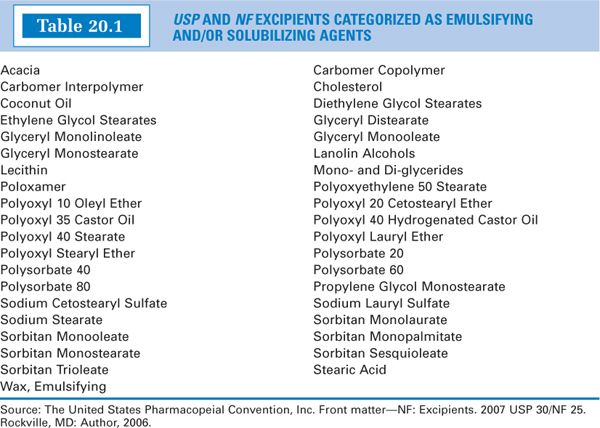

A. Table 20.1 lists the USP 30/NF 25 articles categorized as surfactants and emulsifying agents (8).

B. Water-soluble polymers

The water-soluble or hydrophilic polymers may be grouped either by their origin or on the basis of their electrical charge (4).

1. Based on their origin, there are three classes of water-soluble polymers: natural polymers, derivatives of cellulose, and synthetic hydrophilic polymers.

a. The natural polymers include polysaccharides, such as acacia, agar, pectin, sodium alginate, xanthan gum, and tragacanth, and polypeptides, such as casein and gelatin.

b. The cellulose derivatives are semisynthetic products, made by chemical modification of cellulose to yield soluble polymers. Examples include methylcellulose, sodium carboxymethylcellulose, hypromellose, and hydroxyethyl and hydroxypropyl cellulose.

c. The synthetic water-soluble polymers include vinyl polymers such as polyvinyl alcohol and povidone (polyvinylpyrrolidone), carbomer (which is a copolymer of acrylic acid), and polyethylene glycols.

2.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree