Every hospital has two “factories”:

- A “good” factory that delivers patient care. In a hospital, this would be the emergency department (ED), operating room (OR), nursing units, lab, radiology, pharmacy, admissions, billing, and so on.

- A hidden but expensive “fix-it” factory. This is the factory that cleans up all the medical mistakes, operational mistakes, and delays that occur in the main factory.

Hospital EDs experience repeat visits from the same patient on the same day. Doctors misdiagnose illnesses 15 percent of the time, according to one BusinessWeek article. If your hospital is typical, the fix-it factory is costing you $25 to $40 of every $100 you spend. If it costs $100 million to run your hospital, you spend $25 million to $40 million on the fix-it factory.

DOUBLE YOUR PROFITS

Most hospitals run on razor-thin margins of less than 5 percent ($5 million in a $100 million hospital). Reducing delays, defects, deviation, and costs by 20 percent ($20 million) would more than double your profits. Just think what saving a fraction of that waste could do for your productivity and profitability! Virginia Mason Medical Center went from losing money to earning over 5 percent.

The urgencies of any business can consume all your time. Fortunately, given the right gauges on your dashboard, it’s easy to diagnose where to focus your improvement efforts, even while you are still working in your business.

I have found that clinicians are hesitant to talk about money or profit, but if you think of it as an indicator of overall success, you might see it differently. Better patient outcomes means lower costs and higher profits. Better patient satisfaction means more referrals, which mean more patients and more revenue. Increasing nurse and doctor satisfaction means less turnover and lower costs. Fewer mistakes mean less rework, lower costs, and higher profits.

The End of Common Sense

When I worked in a phone company, managers used to say that process improvement is “just common sense,” but what I’ve learned is that common sense will only get you to a 1 to 3 percent error rate. Hospitals get to a 1 percent error rate on such things as infection rates and medication errors, but that’s where they reach the edges of human perception—the end of common sense.

When you reach the end of what you can do with one problem-solving technology (e.g., common sense), you need to look to the next level: systematic problem solving and the tools of Lean Six Sigma. The primitive methods and tools that took you to sustainable profitability will take you no further. To turn your cash cow into a golden goose, you will need the common science in Lean Six Sigma to make breakthrough improvements. Here’s what you can accomplish with Lean Six Sigma:

- Double your speed without working any harder. Most hospitals have extensive delays built into their processes. Eliminate the delays, and you can run circles around your competition and delight patients.

- Double your quality by reducing defects and deviation by 50 percent or more. Lean alone has been shown to reduce defects by 50 percent. The Institute for Healthcare Improvement (IHI) estimates that one out of every two patients suffers some preventable harm. Lean could help to lower that rate to one out of three. Add Six Sigma, and you’ve got a recipe for world-class performance. Your hospital could become a zero-harm, high-reliability organization (HRO).

- Cut costs and boost profits because every dollar you used to spend fixing problems now can be refocused on growing the business or caring for patients or passed right through to the bottom line. Instead of wasting 25 to 40 percent of every dollar you spend fixing patients and things that shouldn’t be broken, most of that money can fall through to the bottom line, boosting margins through the roof.

MANUFACTURING AND SERVICE

At an abstract level, there’s no real difference between a service process and a manufacturing one. They both encounter delays, defects, deviation, and costs. One may produce discharged patients instead of disk brakes, purchase orders instead of computers, bills instead of brake liners, but they all take time, cost money, create defects, cause rework, and create waste.

In a hospital, we might focus on medication errors. We might focus on variation in admission, diagnosis, treatment, or discharge delays. We might focus on the costs of medical errors that result in longer hospital stays.

In a hospital, the clinical side is only one element. Defects and delays in issuing bills and insurance claims can cost millions of dollars. This is true in any company, from a family-owned restaurant to a Fortune 500 company. Incorrect bills, missing charges, incorrect purchase orders, overpayments, underpayments, and so on can cost a fortune. Fielding the phone calls and fixing the financial transactions can cost more than some invoices are worth.

Ken Miller, author of We Don’t Make Widgets (Governing Books, 2006), has identified the three common excuses that employees use for why they can’t apply Lean Six Sigma to their service business:

- We don’t make widgets. We do “squishy, intangible stuff” like caring for patients.

- We don’t have customers. Healthcare: we have patients. (As Ken says, “You don’t have patients; you have hostages.”)

- We’re not here to make a profit. Healthcare: we’re here to care for the sick.

Listen to any hospital employee try to tell you why Lean Six Sigma won’t work, and you’ll usually hear one of these three excuses. Sadly, Ken says that these myths can stop an organization from embracing radical improvement. Once you see healthcare as a system of processes done by people to produce a “widget” (e.g., surgery, insurance claim, bedside meal) to achieve a desired outcome (i.e., healing), you’ll be well on the way to understanding how to use Lean Six Sigma to create perfect outcomes for all patients.

TRICKS OF THE TRADE

After a meal at a local Chinese restaurant, my fortune cookie said, “If you keep too busy learning the tricks of the trade, you may never learn the trade.” When I think about how this applies to Lean Six Sigma, it seems obvious that far too much Lean Six Sigma training is dedicated to the tricks of the trade and not enough to the actual trade.

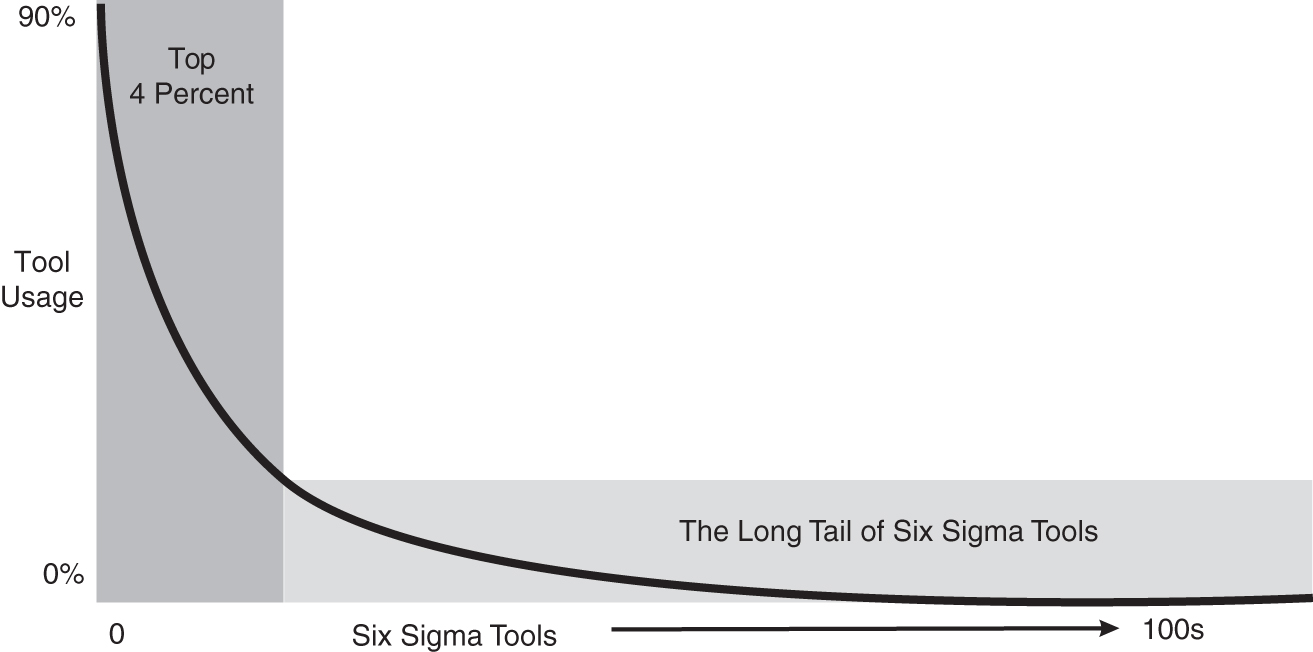

The Long Tail of Six Sigma Tools

To fill the long weeks of Six Sigma training, most trainers cover every tool in the toolbox as if they are all equally important. One trainer admitted that her Black Belt training for healthcare included three days of design of experiments (which healthcare never needs).

A 2003 study by Quality Digest magazine confirmed what I’ve known for years: A handful of tools and methods delivers most of the benefit from Lean Six Sigma. Focused application of these tools will carry you from average to excellent in as few as 24 months while delivering staggering improvements in productivity, profits, and patient care.

In any profession, there are a handful of tools that are used all the time and a slew that are used once in a very long while. This is true of Six Sigma. There is a “long tail” of tools (Figure 6.1).

FIGURE 6.1

The long tail of Lean Six Sigma tools.

Master the Top 4 Percent

One of the principles of adult learning is that participants must use what they’ve learned in 72 hours or they lose 90 percent of what they’ve learned. Most Six Sigma training is done in a week-long format. This means that by Thursday, participants have forgotten Monday; by Friday, they’ve forgotten Tuesday; and by Monday of the following week, they’ve forgotten most of the previous week.

I know what a lot of trainers are thinking: “But we have case studies they do in class.” I have found that unless people apply Six Sigma methods and tools to their own work environment, it just doesn’t stick. Classroom case studies are nice, but they won’t add money to the bottom line. This should be unacceptable.

A handful of tools (the top 4 percent), such as control charts, Pareto charts, and fishbone diagrams, will solve over 90 percent of common problems with defects. If there’s a lot of variation (I call it deviation because variation sounds too benign), throw in a histogram or two.

Master these tools first. Then add the long tail of tools as needed. (Admit it; this is how your home toolkit grew—from a hammer, a screwdriver, and a pair of pliers into a toolbox of gadgets.)

Use company data, not case-study data, to tailor the learning to the participants. Using the company’s data, these tools can be learned and applied in a day, not a week.

If you go to www.qimacros.com/trial/hospitalbook, you can download the QI Macros Lean Six Sigma Software 90-day trial. Use the PivotTable Wizard to create pivot tables. Use the Control Chart Wizard to draw control charts. Use the Pareto Chart Macro to draw Pareto charts. Use the Ishikawa diagram to create fishbone diagrams of root causes.

Stone Age and Space Age Tools

Gut feel, trial and error, and common sense are the primitive tools of the Kalahari or Outback, not the tools of operational excellence. Line, bar, and pie charts are primitive tools that encourage short-term reactive thinking rather than long-term improvement thinking. Every hospital executive’s dashboard I’ve ever seen is some combination of these three kinds of charts. They have no intelligence to help separate signals from noise.

You don’t need to know everything to become a high-reliability hospital. There are a handful of methods and tools that will solve most common problems in healthcare. Isn’t it time to make it easy for the primitive business tribes to embrace these tools?

What do I think are the essential tools? The ones I use most of the time include

Pivot tables to count and categorize defect data

Pivot tables to count and categorize defect data

XmR control charts to show performance over time and detect signals of process changes

XmR control charts to show performance over time and detect signals of process changes

Pareto charts to identify improvement opportunities

Pareto charts to identify improvement opportunities

Histograms to analyze deviations from target

Histograms to analyze deviations from target

Ishikawa (fishbone) diagrams to show cause-effects

Ishikawa (fishbone) diagrams to show cause-effects

Countermeasure and action plans

Countermeasure and action plans

Value-stream maps to identify preventable delays between process steps

Value-stream maps to identify preventable delays between process steps

Spaghetti diagrams to identify unnecessary movement of people and supplies

Spaghetti diagrams to identify unnecessary movement of people and supplies

The QI Macros provide easy, affordable access to these tools. Everything else is overkill for the primitive corporate tribes. Start getting comfortable and feeling safe in the use of these tools, and then you can begin to add in the others.

Learn the Trade, Not the Tricks!

In school, we learned reading, writing, and arithmetic, but we didn’t learn calculus right out of kindergarten. We shouldn’t expect employees to skip grade school and start college, but this is what we’ve done with Six Sigma by covering the long tail of tools—tools employees will rarely use.

Let’s start teaching people how to solve common problems in their businesses. Let’s make them successful with the top 4 percent of tools and then add the long tail as needed. I run into people I trained 15 years ago who are still using these tools in whatever job they’ve taken. When they pull their improvement stories out of their desks to show me, I feel good knowing that the one-day training stuck in their skull, took root, and flourished.

Let’s teach them the trade—and then the tricks. It’s hard to make money in a training business this way, but it’s a powerful way to deliver bottom-line savings and boost profits.

THE FASTER, BETTER, CHEAPER TOOLKIT

Lean Six Sigma is the best toolkit for helping you to think outside the business. The tools are designed to help employees see the business more clearly than ever before.

Lean Six Sigma is a results-oriented, project-focused approach to quality, productivity, and profitability. These reductions translate into cost savings, profit growth, and competitive advantage. And the process is simple:

- Focus on key problem areas by counting and categorizing your delays, defects, misses, mistakes, errors, and deviation.

- Improve by eliminating delays, defects, and deviation.

- Sustain the improvement by monitoring key measures and responding if they become unstable and unpredictable.

- Honor your progress.

If we applied Lean Six Sigma to hospitals, there would only be 3.4 deaths per million hospital admissions instead of 1 per 300, as reported by the National Academy Press (1999).

If you go to www.qimacros.com/training/lean-six-sigma-for-healthcare-webinar, you can watch a free one-hour Lean Six Sigma for healthcare webinar to learn how to apply Lean Six Sigma in hospitals. If you want more in-depth training, take my free Yellow Belt training at www.lssyb.com.

EVERY BUSINESS HAS TWO SOURCES OF CASH FLOW

Cash is the lifeblood of any business. To boost profits, you will want to earn more or lose less. Every business has two sources of cash flow:

- External payers give you money for your patient-care services.

- Internal processes leak cash like a rusty bucket. Why are internal processes a source of cash? Because when you plug the leaks in your cash flow, you get to keep all that money! And it’s a lot of money—a third or more of your expenses. In healthcare, most of this money is lost caring for patients who have been harmed by care. Become a high-reliability hospital; save money, save time, and save lives.

I’d like you to consider that healthcare spends most of its time and money focused on the latest technology for patient care and virtually no time on plugging the money leaks caused by internal processes.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree