So far we’ve looked at ways to solve problems with delay, defects, and deviation using the methods and tools of Lean Six Sigma. After Lean Six Sigma teams have sunk their teeth into a few improvement projects, they often begin to wonder if they are working on the right issues and processes. This seems to be a natural progression: from achieving early success using the improvement tools to wanting to focus the improvement efforts more precisely.

Lean Six Sigma has some excellent tools to help refine your improvement focus. Most people aren’t ready to use these strategic tools until they’ve started to understand the basic methods and tools, however.

I’ve also noticed that Lean and Six Sigma started out as separate methods and tools but have been on a collision course for the last few years. I’ve also noticed a trend in the press toward something called process innovation. Just as Six Sigma eclipsed total quality management (TQM), I suspect that process innovation will become the new catch phrase that encompasses Lean Six Sigma. Regardless of what you name it, the improvement efforts can benefit from more rigorous focus.

FOCUSING THE IMPROVEMENT EFFORT

The focusing process was originally called hoshin planning. I call it laser focus. In this chapter you will learn how to use the key tools required to laser focus your process innovation:

Use the voice of the customer (VOC) to define customer requirements.

Use the voice of the customer (VOC) to define customer requirements.

Develop critical-to-quality (CTQ) measures to link the VOC to your business processes.

Develop critical-to-quality (CTQ) measures to link the VOC to your business processes.

Create a balanced scorecard to focus and align your organization’s mission with both long- and short-term improvement objectives.

Create a balanced scorecard to focus and align your organization’s mission with both long- and short-term improvement objectives.

Select and graph indicators to measure your customer requirements and the progress of the improvement effort.

Select and graph indicators to measure your customer requirements and the progress of the improvement effort.

The planning process feeds directly into problem solving to increase speed, quality, and cost by reducing cycle time, defects, waste, and rework.

Voice of the Customer

If I had asked my customers what they wanted, they’d have asked for a faster horse.

The voice of the customer helps hospitals focus their improvement efforts in ways that will achieve breakthrough improvements in speed, quality, and cost that serve the patient. Stop thinking of a patient as a patient and start thinking of them as a customer. Using the voice of the customer (VOC), business (VOB), and employee (VOE), you can develop a master improvement story that links and aligns multiple teams and improvement efforts to achieve quantum leaps in performance improvement.

Michael George speaks of understanding the heart of the customer, not just the head. To understand the heart, he suggests that you will want to (1) develop strong links to both the core and the fringes of your market, (2) study the behavior of customers to gain insights into how they are using your hospital, and (3) include customers and their knowledge throughout the development process.

The VOC analysis gathers the customer’s needs and wants as a basis for establishing objectives. Only customers can create jobs. So customer satisfaction is a central theme of Lean Six Sigma. There are direct customers (e.g., actual patients, family members, or payers) and indirect customers (e.g., shareholders and government regulatory agencies). Each customer has unique requirements that can be related to your business.

All improvements involve moving from a present way of satisfying customers to a more desired method. Before we can set the improvement processes in motion, however, we first have to define our direction of movement. Where most companies and improvement teams fail is in getting properly focused. To succeed, you will want to focus on your customers’ needs and follow the data.

Once you’ve identified your key measurements for each of these goals, set a “big hairy audacious goal” (BHAG) for improvement. Forget 10 percent improvement. Think zero harm. Go for 50 percent reductions in cycle time, defects, costs, system downtime, decision making, and so on. Go for 50 percent improvements in financial results and customer satisfaction. I have found that when you go for 10 percent improvements, you only get 10 percent ideas. When you go for 50 percent improvements, you get 50 percent or bigger ideas, and you often get 70 to 80 percent improvements. Breakthroughs! BHAGs also force you to narrow your focus to the 4 percent of the business that will produce the biggest return on investment.

Developing the Voice of the Customer

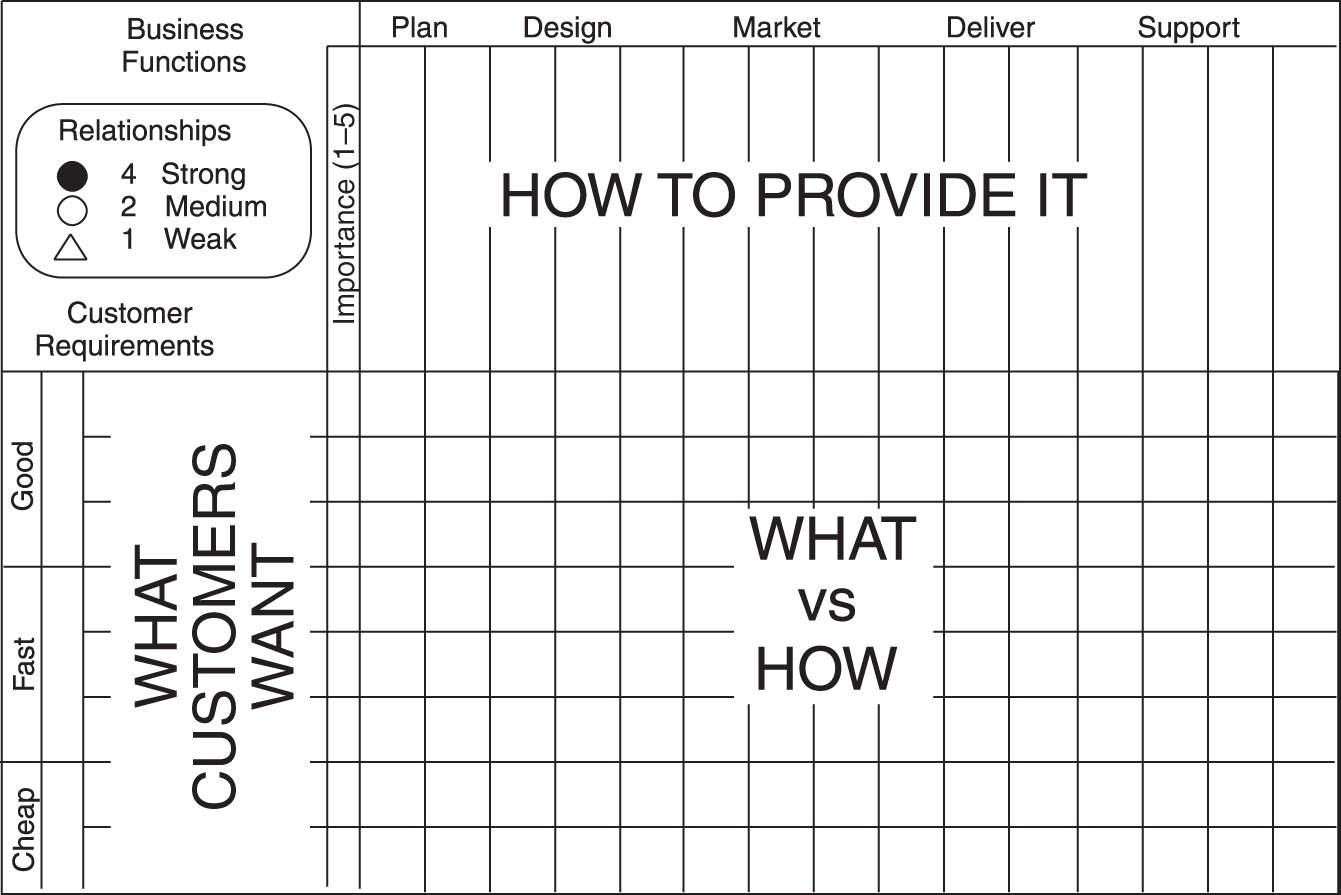

Developing the VOC matrix (Figure 10.1) is easy, but it forces some rigor into your thinking. This is perhaps the power of Lean Six Sigma—all the tools force people to go beyond surface-level thinking into a deeper understanding of their business.

FIGURE 10.1

VOC matrix.

VOC uses the customer’s language to describe what customers want from your business. Using a restaurant as an example to elicit the participant’s VOC for dining experiences, ask, “When you go into a restaurant, what do you want?”

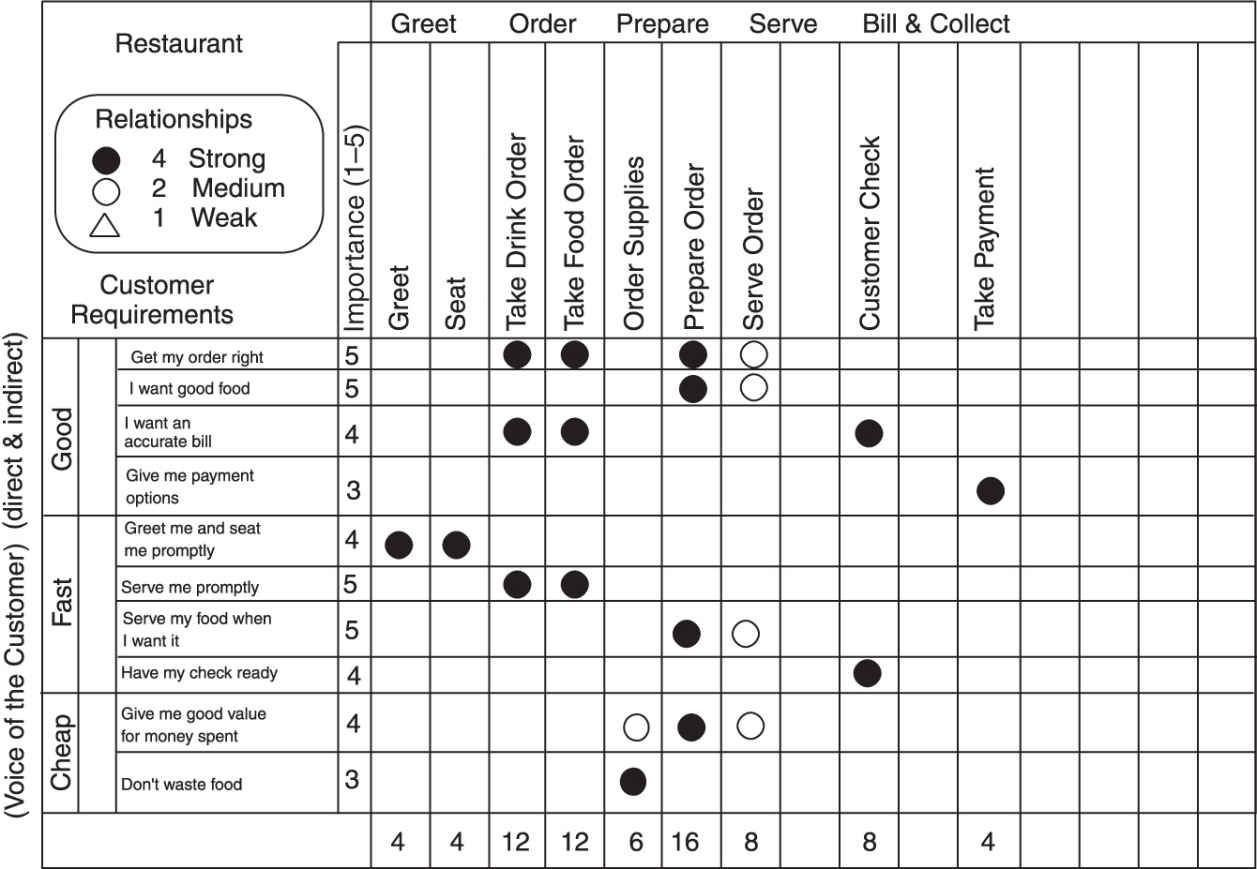

How do restaurants provide the meals? Greet and seat, take orders, prepare and serve food, bill, and collect. What are the most important processes? Figure 10.2 explores how these requirements and processes interrelate. I have found that the VOC has some common requirements no matter what business is involved (Figure 10.3).

FIGURE 10.2

Restaurant VOC.

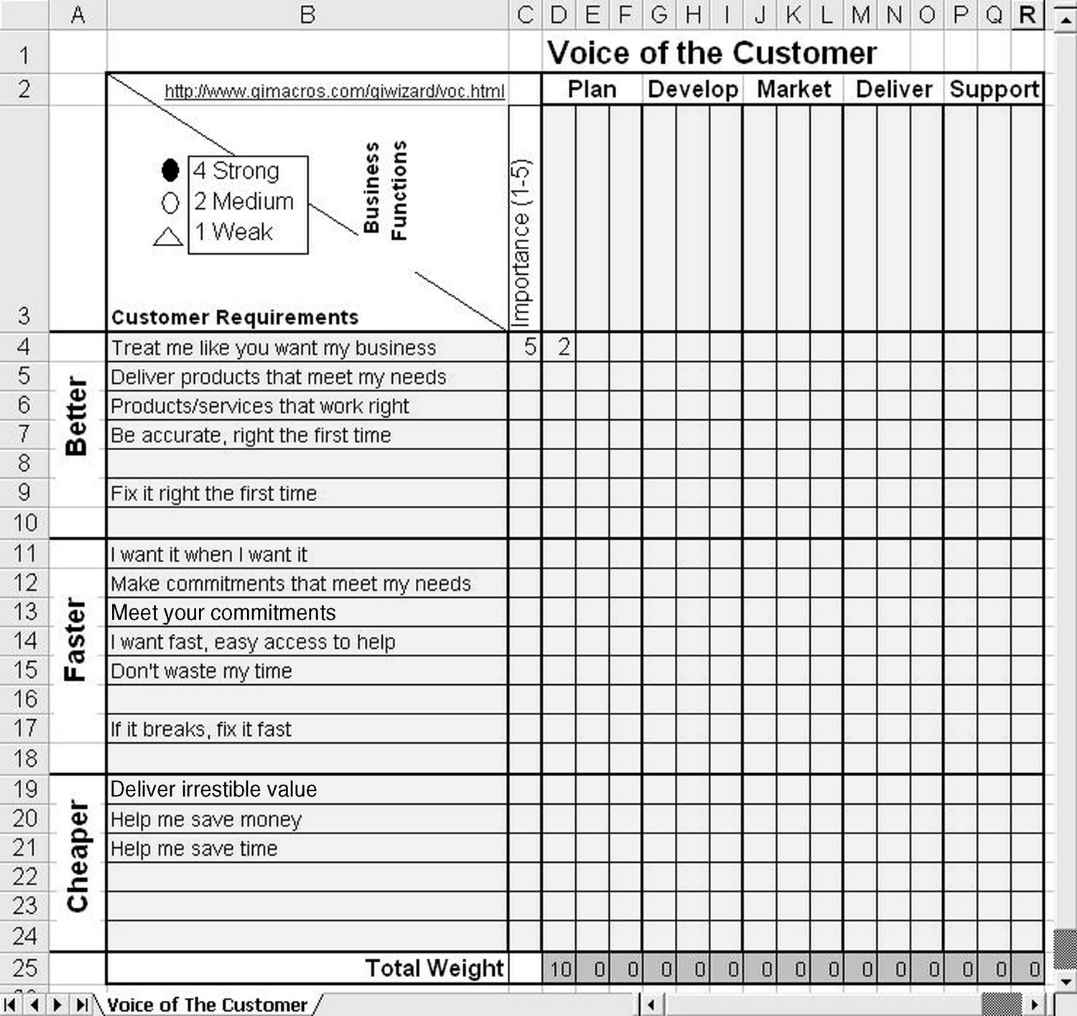

FIGURE 10.3

Macros VOC Template.

Customers say such things as:

Treat me like you want my business (not like a can of corn run over a scanner).

Treat me like you want my business (not like a can of corn run over a scanner).

Deliver products that meet my needs. (Walmart negotiates fixed-price knee replacements and other surgeries with top providers.)

Deliver products that meet my needs. (Walmart negotiates fixed-price knee replacements and other surgeries with top providers.)

Deliver products or services that work right. (No surgical retained foreign objects.)

Deliver products or services that work right. (No surgical retained foreign objects.)

Be accurate, right the first time (zero harm).

Be accurate, right the first time (zero harm).

Fix it right the first time (no readmissions).

Fix it right the first time (no readmissions).

I want it when I want it (not when you can deliver it).

I want it when I want it (not when you can deliver it).

Make commitments that meet my needs (same-day appointments).

Make commitments that meet my needs (same-day appointments).

Meet your commitments (be on time). Don’t make me wait.

Meet your commitments (be on time). Don’t make me wait.

I want fast, easy access to help (staff phones with people who can answer my questions).

I want fast, easy access to help (staff phones with people who can answer my questions).

Don’t waste my time (don’t make me wait).

Don’t waste my time (don’t make me wait).

If it breaks, fix it fast (don’t let harm become permanent because of your mistake).

If it breaks, fix it fast (don’t let harm become permanent because of your mistake).

Deliver irresistible value. (I want fast, affordable, flawless healthcare.)

Deliver irresistible value. (I want fast, affordable, flawless healthcare.)

Help me save money. (Don’t torture me with unnecessary tests or treatments.)

Help me save money. (Don’t torture me with unnecessary tests or treatments.)

Help me save time. (Be on time. Help me get well faster.)

Help me save time. (Be on time. Help me get well faster.)

These are the most common themes I hear from customers. What are your customers saying?

Speak Your Customer’s Language

In Denver recently, tragedy struck a family when a 40-ton construction girder fell from an overpass onto their SUV, killing everyone. I was saddened by the tragedy, but rather than focus on the installation of the girder, my attention focused on the phone call that occurred earlier in the day that could have saved their lives. A driver with highway construction experience called to report that the girder was loose and buckling, apparently unsafe.

After the accident, TV journalists played the call for all to hear. As we listened to the call, the caller kept clearly saying “girder,” and the highway call-center person kept paraphrasing the man’s statement but used the word sign, not girder: “There’s a loose sign?”

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree